In Piping isometrics with large pipe dimensions, using a readymade TEE fitting for taking a branch from the mother pipe is not possible as casting “Tee fitting” is costlier and not so practical. In place of using TEE fittings, it is a conventional method to form a Tee junction by cutting a hole in the mother pipe or header pipe.

Sometimes required branch is not necessary a perpendicular one instead this can also be a tapered branch too and that branch needs to strengthen for handling pressure and any stress development in operation. Rf pad or reinforcement pad adds strength to the joints of those branches. In this article, we will also learn about how to calculate rf pad dimensions.

Similarly, when providing nozzles on any equipment or pressure vessel by cutting a hole into it, that nozzle becomes the weakest part of complete equipment that needs to strengthen to withstand operational pressure.

Here the role of RF pad or reinforcement pad comes to strengthen those weakened parts either of pipe or equipment because of removal of material from the parental body. Reinforcement pads are essential parts and frequently used in large diameter pipes. R pad dimension calculation is a must-to-know thing for any piping fabricator or piping engineer.

In this article we will learn about:

- What is an RF pad or Repad?

- What is the use of RF pad?

- What is a Telltale hole in RF pad?

- How to find if RF pad is required or not?

- The basic design perspective of RF pad

- How to calculate dimensions of Reinforcement pad?

More to Read: What is Piping? How piping is Different from Plumbing?

Table of Contents

What is Reinforcement Pad, RF pad, or Repad?

A reinforcement pad is an important part of any piping system if this has a branch connection without using any branch fittings or this needs to save from any leakage.

You can resemble an RF pad or Repad with a washer that has the shape of a donut in case of installed on some pipe branch. Depends on the required RF pad can also be like the shape of a rectangle but in an Oval shape too.

RF pad or Reinforcement pad is like the addition of an extra layer, same as parent metal on mother line to protect it stress development and joint leakage from branch pipe. This gives extra strength to the mother pipe to handle more pressure and withstand comparatively for more duration.

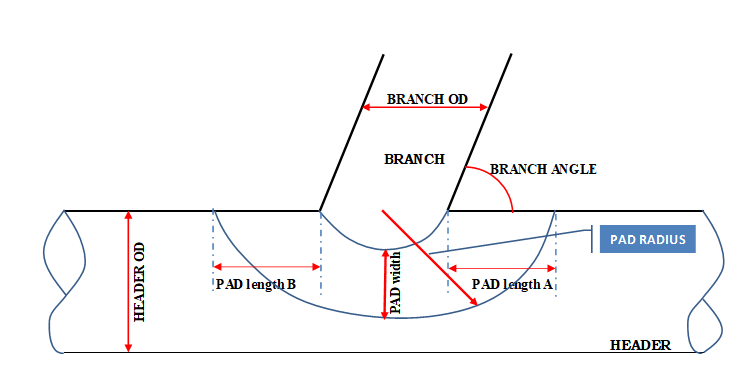

Parameters of RF pad

There are some typical use terminology or parameters you must know if you are in the field of piping. These parameters will help you to identify different dimensions related to the RF pad.

- Header OD: This outer diameter of the header line.

- Branch OD: The outside diameter of the branch pipe that is going to connect with the header line.

- Joint Angle/Branch angle: It is the branch angle of the branch joint. this is always greater than 0º and less than 180º. The 90-degree branch is perpendicular to the header.

- Lateral Offset: Any branch to header can be shifted sideways. its offset angle with respect to the horizontal plane.

- Pad thickness: The thickness of pad material. generally, it is the same as of mother pipe but as per design pressure and temperature, pad thickness can increase or decrease.

- Pad shape: this refers to the outside shape of the RF pad. this can be of 02 types: A. Rectangular B. Oval.

- Pad width: The width of the sides of the pad measure from the center of the cutout. Pad width is the furthest distance from the center of the cutout to the edge of the branch.

- Pad length A: The distance from the one side of the cutline of the branch template as shown in the image.

- Pad length B: The distance from the other side of the cutline of the branch template as shown in the image.

- Pad material: this refers to the type of material that will be used for RF pad fabrication.

What is a Telltale hole in a Reinforcement pad?

The telltale hole is nothing but just another name of weep hole or vent hole. In every RF pad, there are 02 nos. of Telltale/weep/vent holes must be provided of size 06mm NPT. This has nothing to do with providing any strength to the branch but just for vent gases produced during welding. This hole must be sealed with mastic or silicone gel so that water won’t be able to flow inside the RF pad and lead to corrosion.

Purpose of telltale holes

The telltale hole is provided for fulfilling 02 purposes for RF pad:

- Venting out all gases that are produced during welding of branch pipe and RF pad.

- For pneumatic testing of RF pad to check any leakage on it.

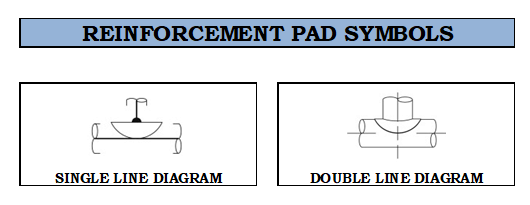

The symbol for RF pad in piping

Like pipe fittings, RF pads also have symbols to denote their presence in the piping system.

Why reinforcement pad is required?

To provide branch on mother pipe we have to cut and remove some part of it which makes mother line weak. Even after welding a branch pipe to the header line, it is not necessary header line will get enough strength to handle design pressure and operating pressure. To provide enough strength we are providing a reinforcement pad to the header line and branch.

RF pad on equipment nozzle or pressure vessel made to ensure its safety and reduce any possibility of failure in future by strengthening it all around.

How to find if an RF pad is required?

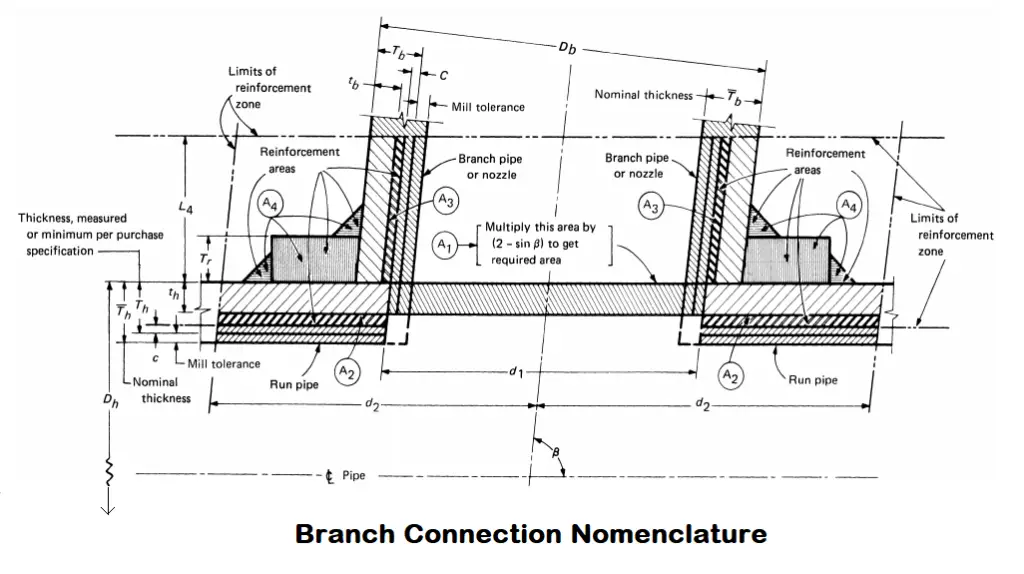

A fabricated branch connection doesn’t have enough strength unless the wall thickness of the header pipe is sufficient to handle the fluid pressure. It is necessary to provide an additional reinforcement pad to sustain the pressure. According to Para 304.3.3 or 304.3.4 of ASME 31.3 if RF pad is required or not can be decided using some formula for which nomenclatures are as below.

From the above image Consider the following nomenclatures for further reference:

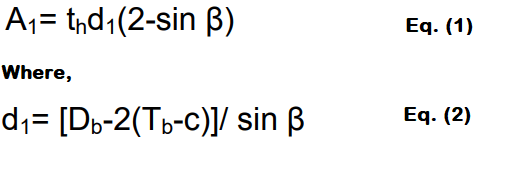

A1 = Area of pipe removed from the header or run pipe

A2 = Extra thickness available in the header pipe. i.e. thickness considered for factors of safety.

A3 = Extra thickness available in the branch pipe. i.e. thickness considered for factors of safety.

A4 = Area of RF Pad & area of welding

L4 = Height of the reinforcement zone

β = Angle between axes of the branch and header

d1 = Effective length removed from the run or header pipe

d2 = Half-width of the reinforcement zone

Db = Outside diameter of branch pipe

Dh = Outside diameter of run or header pipe

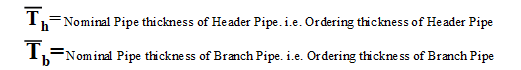

Th = Tb = Thickness after deducting mill tolerance from nominal pipe thickness or ordering thickness of run and branch pipe respectively

th = tb = Calculated pipe thickness as per the equation of para. 304.1 of ASME B31.3 for run and branch respectively.

C = Corrosion allowance

Tr = Minimum thickness of reinforcement pad

The formula used for RF pad requirement calculation:

You can calculate the value A1, A2, A3, A4 using the above formulas for the certain requirement of Branch and header pipe.

- If you will find A1≥A2+A3+A4 then there is a requirement of an RF pad for strengthening the branch connection.

- If you will find A1<A2+A3+A4 then there is no requirement for an RF pad.

Alternatively, you can use a pre-programmed calculator by following this link. Click Here

Basic design details of RF pad

While installing a Reinforcement pad, it is mandatory to provide some features as per Clause 328.5.4.g of ASME B31.3.

- Reinforcement pad thickness must not be more than 1.5 times the thickness of the parent pipe. However, there is a standard practice of using Pad thickness same as Parent pipe thickness

- The thickness of Rf pad should be as per pressure design thickness considered for branch according to stress developed in piping branch connection.

- Vent Hole must be provided of 6mm to release all gases produced during welding of RF pad.

- If an RF pad is made with multiple cuts of the pipe then each of them must have a vent hole.

- Each vent hole must have threads for connecting the male-type threaded nipple for the pneumatic test.

How to calculate reinforcement pad dimensions?

Rf pad dimension calculation is really a tricky way to minimize the wastage of material. For reinforcement pad dimensions calculation, you first need to aware of the following nomenclature that will be used in the reinforcement pad dimension formula:

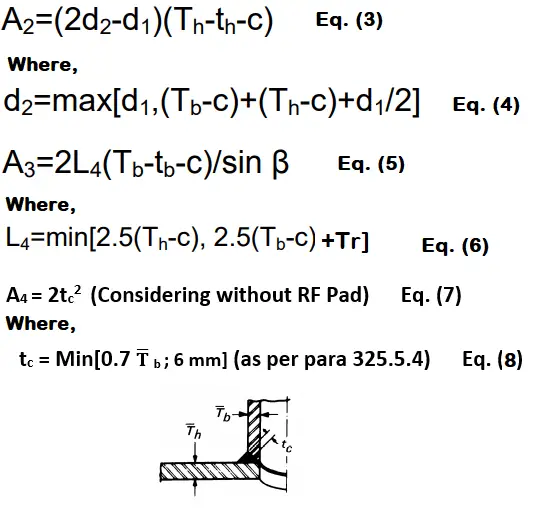

- D: Nominal diameter of the Header pipe

- d: Nominal diameter of the branch pipe

- w: width required of RF pad

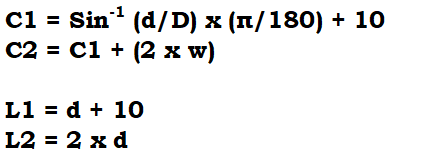

For calculating values of C1, C2, and L1, L2 you can use this formula:

Conclusion

RF pad is an essential part of any branch connection either for fluid flow or for Supporting purposes. from this article we can conclude with the following:

- RF pad or reinforcement pad gives strength of header pipe which get weakened because of removal of material.

- RF provides assurity from any leakage in the future.

- This increases the capacity of the header pipe to handle more pressure.

- After calculation of values of A1, A2, A3, A4, if values of A1≥A2+A3+A4 then RF pad is required else not.

- A vent hole or Telltale hole must be provided on an RF pad of 6mm NPT for venting gases produced during welding.

Quiz Time

Now take a quiz just to be confident about what you learn from here