In the total budget of any oil and gas project, Piping individually shares 17%-20% of the total project cost. In an oil and gas piping project, any delay in piping execution can cost a huge loss in a project in terms of cost as well as time. So, Piping execution planning with Tracking for available drawings, required materials, manpower, and other resources is much important for the successful completion of the project.

Piping execution planning includes piping fabrication planning and piping erection planning as well which starts with data preparation for its various parameters like the number of joints, running meter scope of piping, type of material, count of the valve, and special critical components. Only after having good and efficient basic data of piping a piping execution planner can approach for execution of the job in the real world for a piping project.

This article is written with my experience and my approach towards piping execution planning. Here I will try to give you a basic detail of how to plan for a piping job execution and try to explain the following in my best possible manner:

- Data required for Piping execution planning and how to prepare this?

- How to plan for the piping job, either for fabrication or erection?

- How to identify front availability for fabrication and Erection work?

- Brief on piping job sequence

- Finalizing data preparation, regular updating, and report preparation for piping execution planning.

More to Read: SOP for jacket piping: Types, General requirement, Fabrication, Erection, Testing

Table of Contents

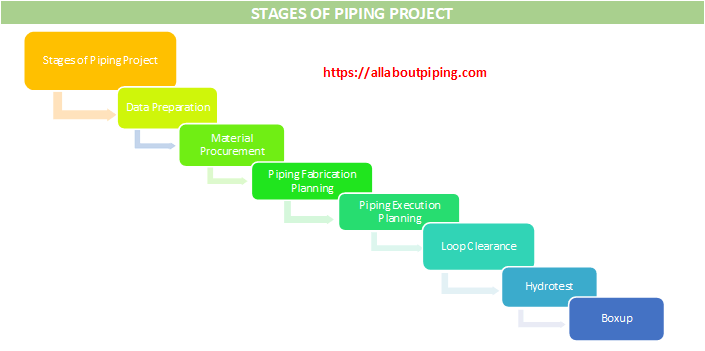

Job stages and Sequence in Piping Project

The field of piping is so vast that only in its construction phase there are many stages and job sequence exists. each phase requires special attention to its planning and documentation for smoothly carrying the next steps of work. Different stages of Piping (apart from different documentation processes) are:

- Receiving IFC (issued for construction) Piping isometrics.

- MTO preparation

- Piping material procurement

- Preparation of IMIR (Inward material inspection Report)

- IBR (Indian boiler regulation act) for IBR fittings.

- Releasing piping fittings as per fabrication plan

- Spool fabrication

- Spool inspection and release note preparation for erection.

- Piping installation and alignment as per Piping isometrics.

- Isometric clearance.

- Mechanical clearance for Piping loops.

- Flushing for internal cleaning for Piping Network.

- Hydro/ pneumatic test of piping systems/loops.

- Box-up, torquing, or tensioning of flange joints.

- Hand over to the client for PSSR (Pre-startup safety review) and other clearance from the licenser (as per contract scope).

Feature Post: What Is RF Pad? How To Calculate Reinforcement pad dimensions?

Data Preparation for Piping Execution Planning

In piping many types of data are required to reproduce a proper plan for job execution, material requirement, and resource allocation. Data required for Piping execution planning are:

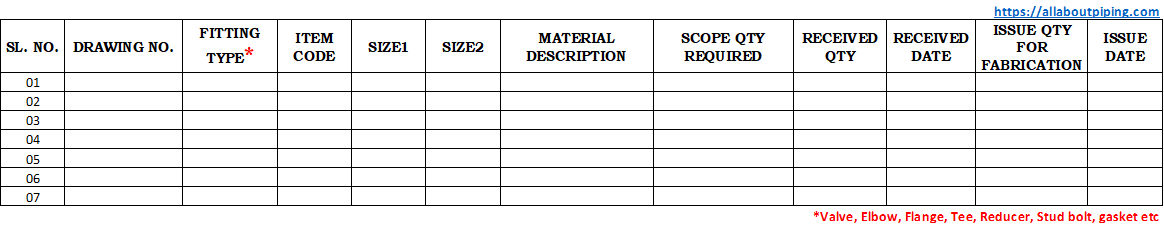

1. Bill of Material

This datasheet will help to identify and plan for the required fitting item for piping job fabrication and execution job. This data is required to prepare in starting phase of the project to avoid any delay or absence of material during the peak time of a project.

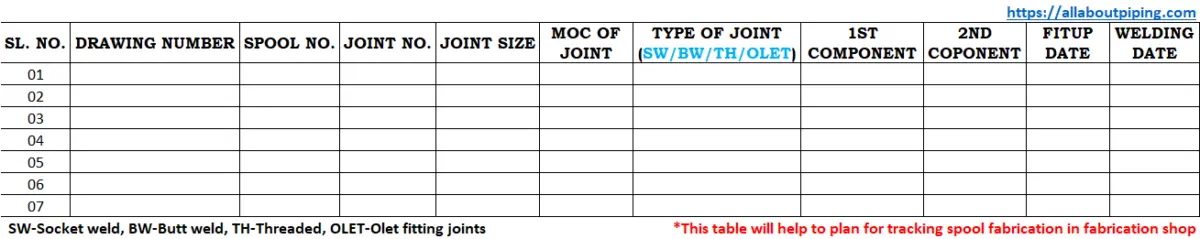

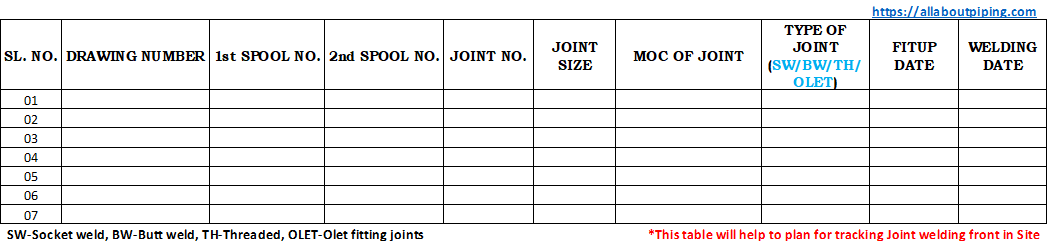

2. Weld Joint Master sheet

This datasheet will help you to track size-wise and material type size joints allocation.

With these data sheets with co-relation of Material available, you can easily find out front available for spool fabrication. For site welding front availability updating daily spool erection in Spool master data.

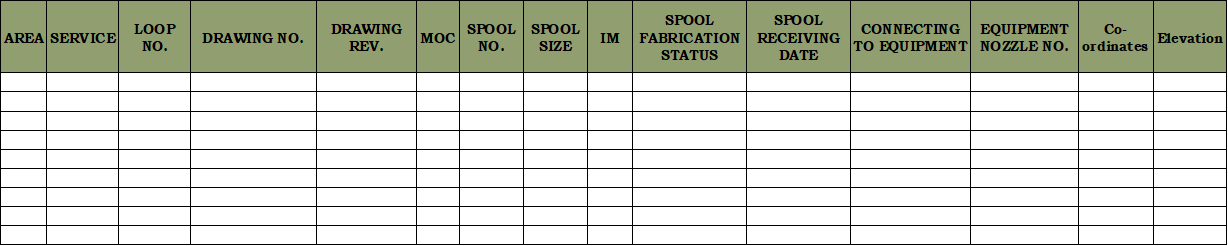

3. Spool Tracking datasheet

You will need this sheet for piping planning when the actual erection work of spools will start on site. This data is required to prepare to maintain hassle-free planning and setting monthly erection targeted. Data extracted from this sheet will also help track to find out available erection front and any constraints for work.

Piping in the oil and gas industry has a complex network that needs to closely monitor spool by spool. To track each and every spool that is going to installation on its location is so much important. So, This type of data preparation for piping execution planning in Oil and gas is very vital.

More Resources: What is Piping Isometric drawing? How to Read Piping Drawing?

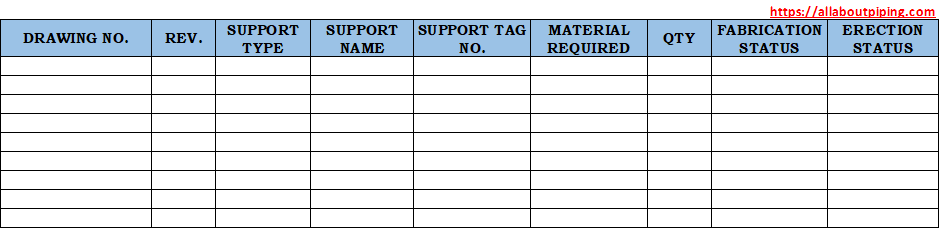

4. Datasheet for Supports

In the oil and gas project planning for the piping project, Planning for support installation is as much important as planning for spools because position a line on its co-ordinate will not be possible with Piping supports.

In type there are 04 types of Supports that need to plan:

- Primary Supports: The Supports that are going to attach with Pipe directly. Like; Shoe Supports, Saddle Supports, Wear Pad

- Secondary Supports: Supports that are not directly attached to pipes but required as per design because of Piping stress, metallic expansion, etc. For example, Guides, Line Stopper, etc.

- CPS (Civil Pipe Supports): Support that is connected to the Civil part (Including structure) of project construction for supporting the Piping system.

- SPS (Special Pipe Supports): The Pipe supports are not as per design details provided on standard support drawing but required as special and variable cases of piping requirement.

5. Datasheet for Installation of Equipment for Spool Erection

For Piping execution planning and spool erection, It is quite important to have data for the installation of equipment from which we can start erecting spools from its nozzles. In unit Piping, starting piping erection from an equipment location is a better option to avoid any misalignment of pipe flange joint with equipment nozzle.

Equipment layout and plot plan can help in a much efficient way to find out area-wise equipment distribution and installation of each equipment on a single sheet. Tracking equipment location, its erection status, and clearance for piping erection help oil and gas piping execution planning or any piping planning a lot.

More to Read: Heat Tracing in Piping: Types, Working, Use, Installation, Comparison

Piping Project Execution Plan

After all Data preparation for piping planning, the real work of a Piping execution planner starts. From identification of material available to pipe spool fabrication in fabrication shops and front identification for spool erection.

A piping project planning is essential for the successful completion of piping work in oil and gas. Without one, your Project management and planning will likely to affected by many factors like missed deadlines, scope creep, lack of resources, Deficiency of Workforce, and cost overrun.

The basic requirement of any Piping Project in oil and gas or any other Industries Can be summaries in the following steps:

- Define Scope of Piping in terms of Total welding and Erection scope with respective supporting.

- Track for all the material (fittings) and resource availability for starting piping work.

- Identify the availability of front for piping fabrication and spool erection.

- Organize the defined responsibility for Each stage of work like; Piping fabrication engineer, Supervisor, Material co-Ordinator, QA/AC, Consumable store person, and manpower allocation for each job.

- List out all sequential and Necessary jobs with their respective required resources.

- Develop a standard procedure for executing any job with all documentation required.

- Develop an effective progress reporting and tracking system for all data required for piping planning.

- Find out any on-field blockage and challenges and call a meeting to sort out all problems.

- Time to time monitor and control, progress and performance of each sub-activity to keep the progress of the Piping fabrication and erection planning aligned with project requirement.

- Preparing Daily, weekly, and monthly data sheets with updation of progress for creating a look ahead of Piping project execution in oil and gas piping planning.

Front Identification for Piping Execution

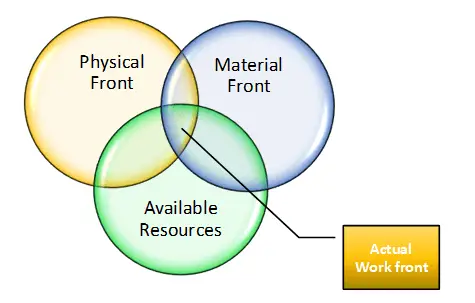

Identification of the work front is so important that if you failed to do that you can never be achieve anything on time in the Piping project. In fact, Identification of the work front is the first step towards oil and gas execution planning.

Preparing data and extracting details from its just an approach of data science that helps us with project planning. In my point of view, You have an approach towards three Elements of the project for the determination of the front available for piping execution planning.

- Physical Front: I define this as the space available for the erection of spools either in a Pipe rack or with equipment. This element of project planning provides space for executing work on the ground level.

- Material Front: Even if you have space available for piping erection but spool fabrication is not completed yet then the available physical front will not give its effect towards completing the target. To inline with the front going to available physically you need to plan for spool fabrication as well for optimum use of project duration.

- Available Resources: Even if material and Physical front are available with you then also without resources you will not be able to plan for piping job execution. So, it is important to plan parallelly towards all three elements towards result-oriented piping planning.

Planning for Piping Fabrication

Spool fabrication planning consists of equal and parallel planning for material, resource, and manpower. All aspects of Spool fabrication planning can be summaries as:

- Data preparation for Spool-wise fittings requirement.

- Tracking for required and available fitting for fabrication.

- Checking for available, approved IFC piping isometric drawings for fabrication.

- Deciding priority of spools required as per erection sequence and physical front going to available.

- Issuing drawings as per material availability and work front.

- Fabrication of spool and getting the clearance with Pre-heating, Post-heating, and NDT (Non-destructive testing) for the high-quality weld joints.

- Painting of spool as per required Dry film thickness (DFT).

- Preparing spool clearance note and Dispatch to the site for erection activities.

Planning for Piping Erection

Erection spools with respect to physical and material front can be even easily identified with help of Plant and instrument diagrams for spool going to connect with equipment and also with Help of GAD (General arrangement drawings) of piping, Spool erection planning become easier.

The activity needs to be done for Piping Erection planning need to do can be summaries as:

- Identification of drawing that starts from equipment with help of P&ID.

- Identification of Drawing that can be installed on pipe rack with help of GAD.

- Arranging lifting tools and lifting equipment for erection.

- Managing for required resources as per piping erection planning.

- Getting Fabricated spools as per erection plan given to fabrication shop.

- Erection of Spools.

Sometimes it is quite mandatory to look after some special spools that must be erected before further structural or civil to avoid any blockage of space during erection. Identification of these spools and erection of these at specific times is also important to reduce piping time and manpower cost.

Progress Report Preparation for Planned Work

Piping project reports timely updates on the progress of the piping project as a result of the plan. Making a Regular project status report is very important because this helps you to keep the track of each activity of piping execution.

Making Project Progress reports keeps you updated and ahead of each stakeholder because you will already have all the answers and will be ahead in the game. A progress report show and tell you about the status of your plan. If your project is going according to your plan this makes you confident and project with timely completion.

Things you must include while preparing a progress report are:

- Name of Project.

- Pictorial Presentation of progress, whether you are on track or not as per plan.

- A quick summary of scope and progress in Area-wise bifurcation details.

- Mention any milestone achieved during progress month.

- A high-level overview of the progress of each area.

- The highlight of any issue or challenges of the project.

- Any other additional notes or highlights of the project.

Conclusion

Project planning is a crucial step within the overall project management:

- Ideation – Project planning is a crucial step to collate ideas from the customer, vendors, your team, top management, and your thoughts and put them in learning. This entails us to research further and know the gaps if there any.

- Reflect from the previous projects – Project planning is employed to document and proper the ways and identify the risks and treat them in order that this project doesn’t go wary. Learning from the previous experience.

- Document the Project Plan – Document everything necessary such as risks, previous project failures and work around, the resources needed, time frame, cost and budget, contingency plan, etc. This ultimately helps the project for the successful completion

Piping Execution planning gives you an idea and tracking of your work that what this will need to complete, how much time it is going to take for completion, and its bottleneck and other challenges.