Residue upgradation facility, or RUF’s, were first developed in the mid-1970s, with the creation of Norsk Hydro’s Arctic Catchem plant, which processes balance residue generated after vacuum distillation and full conversion hydrocracking unit. RUF’s are now commercially available around the world.

RUFs are also used to upgrade the residual waste stream from pulp and paper mills, metal smelters, oil refineries, chemical plants, textile mills, brewing facilities, and plastics manufacturers. Residues are typically lignin-containing products resulting from pulping, bleaching, and cracking processes.

Featured Article: Fugitive emissions testing, Standard and valve stem packing

Table of Contents

What is Residue upgradation facility or RUF?

A residue upgrade facility (RUF) is a chemical-processing plant that leads to the conversion of low-value waste streams into valuable products such as organic solvents, hydrogen, and polyurethane. RUFs use technology such as thermal depolymerization and membrane distillation to extract useful chemicals from waste streams.

The wastes are typically sorted so they will contain the least amount of contaminants before being heated to 250 degrees Celsius in a high-temperature furnace. The end result is a concentrated mixture of hydrocarbon chemicals that can then be used to make valuable products.

The residue is the unwanted or unused portion of any material that has been produced in a process. The residue stream is comprised of solid material that has not been used in the production of another product.

Residue from modern refineries is often made up of fibrous lignin, while residues from refineries and chemical plants have a higher content of inorganic materials. Current treatment options for residue streams include landfilling, boilers/burners, waste incineration, composting, and biogas production.

More Resources: What is Steam Blowing? Steam blowing Type, procedure, and Principal

Why Residue Upgradation facility is Required?

Because of the huge demand and consumption of fuels, energy and petrochemical products increased tremendously and because of the reserved amount, crude oil amount is decreasing and quality is also declining gradually.

Therefore, this is the need to fully utilize any heavy residue of crude oil and the limited petroleum resources, So the residue upgradation facility comes in the process. Consequently, the interest in science is focused on diverting the crude residue fraction from its traditional use as a heavy fuel component to process, either to convert the residue into high-value products.

All refiners are equally concerned about upgrading the available crude oil for refining and upgrading the residue to get more lite distillates required for transport fuels and to provide the needs for the other concerned industries using petroleum products such as fertilizer and petrochemicals.

The Basic reason for giving special attention to residue upgrading is that India has fewer options than to import crude oil with a maximum percentage of the residue. The goal for up-gradation of heavy oil and vacuum residue is to decrease viscosity and boiling point, demetallation, desulfurization, level of other impurities and to increase H/C rato with high commercial values.

Many types of synthesis processes and technologies have been developed to upgrade heavy oils, waste materials, and vacuum residue. Among all technologies for the conversion of heavy oils and VR, slurry-phase hydrocracking is the most considerable process.

Types of Residue upgrading process

Technology for upgrading heavy oil in residue upgradation facility for bitumen and the residue is broadly divided into carbon rejection or hydrogen addition process. Carbon rejection redistributes hydrogen among various other components and results in fraction with increased H/C (hydrogen/carbon) atomic ratio.

On the other hand, the Hydrogen addition process involves the reaction of heavy feeding of an external source of hydrogen which results in an overall increase in the H/C ratio. Within these broad ranges, all upgrading technologies can be divided as follows:

- Carbon rejection process: Visbreaking, steam cracking, coking, and fluid catalytic cracking.

- Seperation process: solvent deasphalting.

- Hydrogen addition process: hydrocracking, fix bed catalytic, hydroconversion, ebullated catalytic bed hydroconversion, hydrovisbreaking, hydropyrolysis.

- Nanoparticles upgradation

- Biological processing of heavy oil and residue.

Carbon Rejection process

For residue upgradation facility the carbon rejection process is one of the most important and old methods of upgrading heavy oil and VR (vacuum residue) which is used since 1913. In this process, the heavy oil and VR are heated under inert atmospheric pressure to fracture them into smaller molecules.

Internal hydrogen attached to carbon molecules is redistributed among the different components so that so fractions increases and their H/C ratio too. In this process induced carbon coke is formed.

While, during the hydrogen addition process, the H/C ratio of the heavy oil and VR was used to increase because of external hydrogen source injection in presence of a suitable catalyst.

Different methods under carbon rejection process for residue up-gradation facility are as follows:

- Visbreaking: this is the oldest and cost effective option for residue upgradation. However during this process, ashaltene content does not vary in product. Therefore, stable fuel oil obtained. This process is suitable in those areas which demand relatively low fuel.

- Steam Cracking: it is a petrochemical process in which heavy oil and residue are broke down into smaller saturated hydrocarbon. It is the principal industrial method for producing the lighter alkene including ethene and propene.

Steam cracker units are facilities in which heavy oil and VR such as Neptha, liquified petroleum gas, ethane, propane or butane is thermally cracked by using steam. - Coking: Cocking is very severe form of thermal cracking that converts the heavy oil and low value residue to valueable distillate and petroleum coke. In refineries faclities like residue upgradation facilities, it is processed and as a result petroleum coke is produced.

- Fluid catalytic cracking: This is the conversion process used in petroleum refineries to convert the unsaturated hydrocarbon to lite petroleum products. The cracking of petroleum hydrocarbon was originally done by thermal cracking is now replaced by catalytic cracking, which yield greater volume of high octance rating of gasoline.

More Resources: Design of Piping System: A small brief

Separation process or Solvent Deasphating

Solvent de-asphalting involves the physical separation of constituents from the heavy oil and VR to their molecular weight with physical separation at their boiling point. The residues are mixed with a paraffinic solvent as propane, butane, n-pentane, and n-heptane.

Asphalting and other impurities are insoluble in the paraffinic oil and the insoluble portion is separated from the mixture. High energy costs, low fuel, and limited use of the de-asphalting products are the limitations of this process.

Hydrogen Addition Process

Hydrogen addition process or hydrogenation is a chemical reaction where molecular hydrogen in presence of catalysts like nickel, palladium, or platinum is mixed to heavy oil or vacuum residue for its crude upgradation.

The process is commonly employed to reduce saturated organic compounds. The Hydrogen addition process typically constitutes the addition of pairs of hydrogen atoms to heavy oil. In this hydrogen reduces double or triple bonds from hydrocarbons.

Residue upgradation by Nanoparticles

Nanotechnology plays a vital role in residue upgradation as an alternative technology for in-situ heavy oil upgrading and recovery enhancement. Nanoparticle catalysts are one of the important examples of nanotechnology applications.

Nanocatalyst provides unique catalytic and sorption properties due to their exception of high surface area to volume ratio and active surface sites. In situ catalytic conversion or upgrading of heavy oil and VR with the aid of multiple metallic nanocatalysts give and cost-effective and environmentally friendly technology.

Biological Process of heavy oil

Biological processing of heavy contents of crude oil gives less severe processing conditions and higher selectivity for refining. Biochemical processes are expected to be low in demand for energy processes and certainly ecofriendly.

As biological processing of heavy crude oil offers less severe processing conditions in refineries and higher selectivity to specific reactions to increase net distillates. It is proposed that the microorganisms, capable to degrade a heavy fraction of VR can be an opportunity for residue upgradation.

Reactor bed types in Residue upgradation facility

Functionality and process steps of reactor changes with its bed types where heavy crude oil and VR are being upgraded to form high-grade products. According to the operational perspective, there are 03 types of reactor bed available for residue upgradation facility:

- Fixed bed reactor

- Ebullated bed reactor

- Moving bed reactor

Fixed bed reactor

In a fixed bed reactor, Catalyst beds are connected in series. It is normally constructed with a combination of 03 reactors at least that run simultaneously to provide the best conversion. With time catalysts becomes inactive. So, annual maintenance to clean and regenerate the catalyst.

In a fixed bed reactor, there are many cylindrical tubes filled with catalyst pellets with reactants flowing through the bed and being converted into products. These fixed catalyst beds may have many configurations like:

- One large bed

- Several horizontal bed

- Several parallel packed tubes

- Multiple bed in own shells

These different configurations may be adapted depending on the need to maintain and control the temperature within the system. Series connections of two reactors with an option to dose oxidant between the stages enable under optimal conditions to increase the production rate. Catalyst size ranges from 0.25cm to 1.0cm in diameter. which can be in the shape of a sphere, cylinder, or any random shape.

Advantage and Disadvantage of fixed bed reactor

Fixed bed reactors have many following advantages and disadvantages as follows:

| Advantages | Disadvantages |

|---|---|

| High conversion rate per unit weight of the catalyst | Difficult to control the temperature |

| Easy to build and Install | Temperature gradients may occur |

| More contact surface area between reactant and catalyst with respect to other types of reactors. | Catalysts are difficult to replace |

| More production rate because of increased contact surface area. | Because of channeling ineffective area inside reactor may form |

| Low cost of construction, operation, and maintenance | A side reaction is possible |

| Effective even at high temperature and pressure | Heat transfer to or from the reactor is possible |

Ebullated Bed reactor

Ebullated bed reactors are a kind of fluidized bed reactor that utilizes temperature for boiling to achieve the appropriate distribution of reactants and catalysts. The ebullated bed technology utilizes a three-phase reactor and is most applicable for exothermic reactions and also for heavy oils and VR which are difficult to process in fixed beds because of the high levels of contaminants.

An ebullated bed reactor gives high-quality continuous mixing of liquid and catalyst particles. The advantages of a good back mixed bed include excellent temperature control and reduces plugging, channeling, and pressure drop. The catalyst used here is 0.8mm in diameter and in a fluidized state (in motion) throughout the operation.

Advantage and disadvantage of Ebullated bed reactor

The advantage and Disadvantages of an Ebullated bed reactor or fluidized bed reactor are as follows:

| Advantage | Disadvantage |

|---|---|

| Uniform particle mixing | Increased reactor vessel size |

| Uniform temperature gradients | Pumping requirement and pressure drop |

| Ability to operate the reactor in a continuous state | Particle entrainment |

| Erosion of internal components | |

| Pressure loss |

Moving bed reactor

A moving bed catalytic reactor doesn’t require expensive stoppages. In a radial flow moving bed reactor, a moving bed of catalyst flows downward within the permeable wall. The catalyst then enters a converging section and is discharged through a rotary valve. In moving bed reactor used catalyst is always need to change with fresh catalyst.

The moving bed fuel reactor can be operated in the counter-current or co-current mode based on the gas-solid flow contact pattern. In a counter-current moving bed reactor, Gaseous components move in the opposite direction with respect to solids. While in Co-current gaseous components moves in the same direction as solids.

A moving bed reactor is also called a slury-phase reactor in which multiphase system operation occurs for heavy oil or VR upgradation.

Advantage and Disadvantage of moving bed reactor

| Advantage | Disadvantage |

|---|---|

| Designed to give sufficient time for gasification of Solid fuel particles | Need 02 or more reactor to operate for fuel conversion |

| Solid distribution can be precisely controlled | Gas velocity need to be precisely minimum for smooth operation |

| A chemical reaction in this reactor is net endothermic | Generation of fine particles by abrasion of catalysts |

| The permeable operational condition provides complete separation of Solid and gaseous particles | Catalyst removal by filtration can initiate problems with plugging of the filter |

| Very less or no loss of heat because of adiabatic chemical processing | Higher catalyst consumption |

| Adaptability to either batch or flow processing | Back mixed flow and volume of the reactor are not fully utilized |

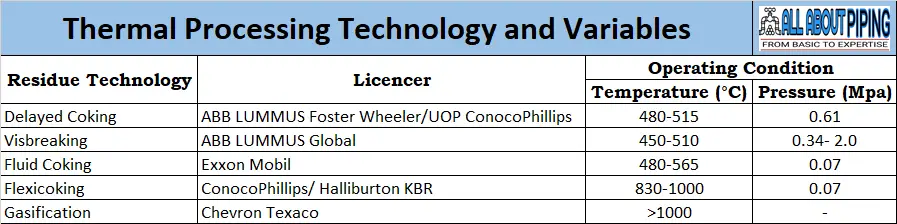

Thermal Process Technology and Reaction Conditions

Reaction among various components depends on various conditions. Some of thermal process and reaction conditions are as follows:

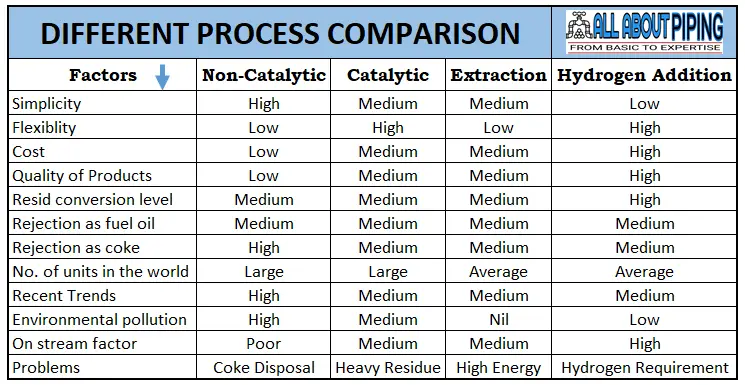

Comparison of Different Process

The comparison among different process used for Residue up-gradation are as follows:

Operating Variable of Residue upgradation facility (RUFs)

There are many variables on which upgradation of residue and heavy crude oil depends are as follows:

- Feed Stocks variables: This describes the properties and charaterstics of feed crude oil or Vacuum residue. There factor of defining these variables are:

- Chracterisation factor

- Degree of reduction

- Conardson carbon

- Sulphur content

- Metallic constituents

- Low feed stock characterisation factor

- High carbon residue increase coke yield

- Quality of gas oil end point

- Engineering Variables: These variables gives idea about process, upgradation, and refining process to decide.

- Crude oil batches

- Semi countinuous or continuous

- Capacity and size factor

- Coke removal equipment

- Coke handaling

- Storage and Transportation

- Operating Variables: Various variable in delayed coking process for residue upgradation facility are:

- Temperature

- Pressure

- Recycle ratio

- Transfer temperature

- Coke chamber pressure

- Higher Temperature: This results in more vaporization of the inlet material causing low coke yield. A furnace outlet temperature of 485-505 °C is maintained. High temperature results in hard coke while coke is softed when too low temperature is maintained.

- Higher Pressure: A higher pressure results in coke and gas yields which is undesirable as basicobjective is to improve the yield of distillation with less quantity of coke.

- Higher Recycle ratio: This results in higher coke and gas yields. Lower recycle ratio is always desirable for higher yield of liquid products.

Conclusion

According to the hike in demand for fuel and petrochemical crude refining system needs to be modernized. RUF or Residue upgradation facility plays a vital role in the extraction of high-grade fuel from the heavy oil and vacuum residue.

There are different methods through which residue upgradation can be processed and accordingly type of reactor selection has been done. Each type of reactor has its specialty and limitation. Catalytic hydrocracking is one of the most effective processes for residue upgradation.