Different types of butterfly valves have different applications based on their features and functionality. A butterfly valve is a mechanism that can regulate the flow of fluid in the large nominal diameter pipe by the quarter-turn rotation of a disc.

A rod passes through the center of a disc and this rod is connected to an actuator that controls the motion of the disc. The disc portion can be either parallel or perpendicular to the direction of fluid flow.

A butterfly valve is different from other valves because the disc of the valve is always in the flow causing a pressure change for any position of the valve.

More Resources: What is a Knife gate valve? Type, Working, Part, Use, Benefits,

Table of Contents

Why it is called butterfly valve?

Some of the valves are named for their shapes such as ball valve, Globe valve, Needle valve, etc. While some of them are named for their movement and function. For eg: Gate valve, Plug valve, pinch valve. A butterfly valve is named because of the movement it makes.

It gets its name as butterfly valve because its disc movement is similar to a wing of a butterfly. The rod of the butterfly represents the butterfly’s body while its disc movement is like butterfly wings.

Component or Parts of Butterfly Valve

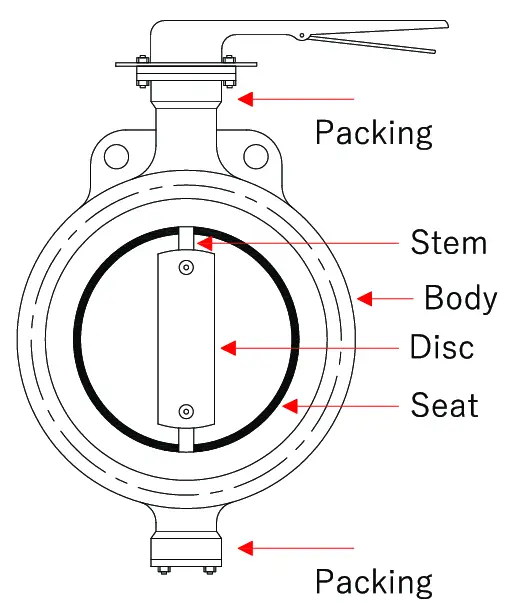

There are mainly four components in a butterfly valve: Body, Disc, Stem, and Seat.

Valve body: the body of the Butterfly valves fits within two pipe flanges, the most common body design is lug and wafer type.

Valve Disc: The disc is the component of the valve that controls the flow. For improving flow, sealing, and operation, there is a variation of design and orientation

Valve Stem: The stem of the butterfly valve consists of a one-piece or two-piece shaft design. Stem design shall prevent galling potential between similar corrosion-resistant materials.

Butterfly valve Seat: To provide shutoff, the seat of a butterfly valve utilizes an interference fit between the disk edge and the seat. The seat may be bonded, pressed, or locked into the body.

More to Read: What is Disc Valve Diffuser? Purpose of Valve Diffuser in Piping.

Types of Butterfly Valves

Depending on the different criteria like disc design, Type of connection, Operational method there are many types of butterfly valves as follows:

- Based on Disc Design

- Concentric butterfly valve

- Eccentric butterfly valve

- Single-offset

- Double offset

- Triple offset

- Based in piping connection

- Lug type

- Wafer type

- Flanged type

- Butt-welded types

- Based on operational Method

- Manual operated butterfly valves

- Lever operated

- Gear operated

- Automated actuation

- Electric

- Pnumatic

- Hydraulic

- Manual operated butterfly valves

- Based on Seat Material

- Soft seated

- Metal Seated

Based on Disc Closure Design

According to use and functionality, the butterfly valve disc is designed to with different axial positions with respect to its body. the explanation for each type are as follows:

Conentric Butterfly valves

“Concentric butterfly valves” or “Zero offset butterfly valves” are designed with no offset of the disc from its stem. The valve seals via interference along the disc edge at the stem between and the rubber seat.

The Rubber seated valve has the lowest working pressure rating, i.e. up to 250 psi, and can withstand heat up to 400°F. Its rubber seat encases the body to prevent contact with the material which stops any foreign material to get mixed into the media.

Eccentric Butterfly valves

In the case of the Eccentric butterfly valve, the Disc of the valve has an offset from the axis of the stem. Here 02 types of eccentric valves are there:

1. Double eccentric butterfly valve and

2. Triple eccentric butterfly valve

For details of both types of valves please read: What is Triple Offset Butterfly Valve? Definition, Design, Application, Code, and standard

Based on Connection Type

The need for different types of connections for different media develops many types of butterfly valves according to their connection type with piping as follows:

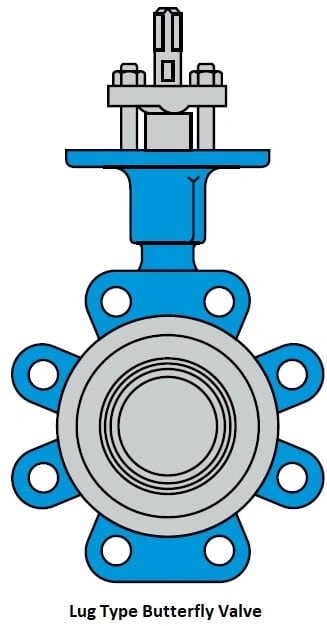

Lug type butterfly valves

Lug types of butterfly valves have threads at both sides of the valve body that allows them to be installed into a system using sets of bolts only. This valve is installed between pipe flanges, which allows this setup to disconnect the piping system by disturbing the other side of the valve connection.

Lug-type valves are extremely resistant to chemicals and solvents and can handle temperatures up to 200°C. It can withstand the pressure of 150 psi when installed between 02 flanges and 75 psi when installed at the dead-end of the pipe.

The lug-type body provides passage to bolt holes that match with same of the flanges.

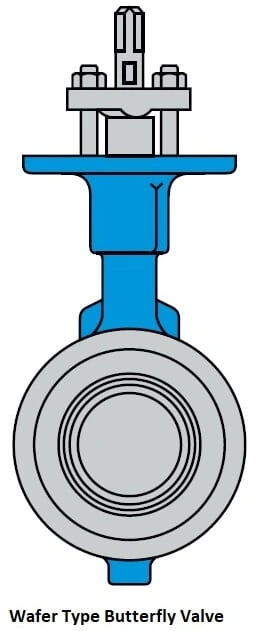

Wafer type butterfly valves

The wafer-type butterfly valve is designed to maintain pressure seal against bi-directional flow differential pressure of the fluid. It prevents any backflow in the system designed for unidirectional flow.

The wafer body is placed between the pipe flanges and the flange is bolted around the valve. A wafer-type valve is easy to install but this can’t be used for the Isolation of fluid flow.

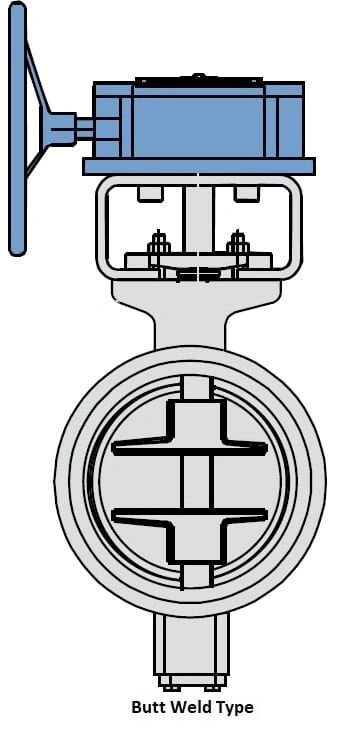

Butt welded butterfly valves

This type of valve is used in high-pressure lines. These butterfly valves are manufactured with metallic edges that can be welded directly with the pipe.

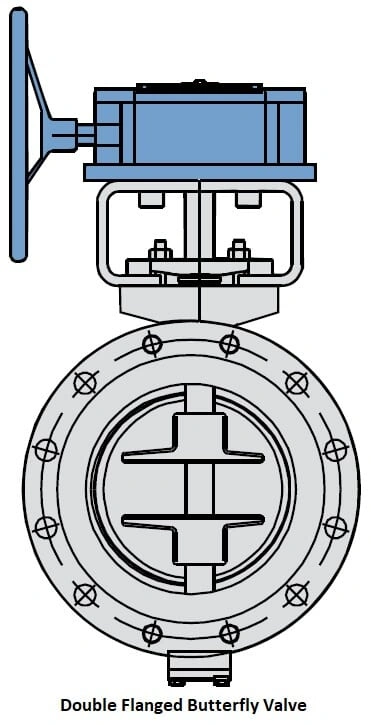

Flanged type butterfly valves

Flanged butterfly valves are having flanges as end connections which can be directly bolted with pipe flanges.

These types of butterfly valves are most suitable for high-pressure and high-temperature piping. In each double flange butterfly valve, there is a total of 08 Nos. of body bolts that connect through threaded holes in the body of the valve.

04 bolts on each flange, 02 on the upper part, and 02 on the lower part of the body near the stem of the valve.

Butterfly Valve Materials

Like other types of valves, butterfly valve comes in a wide range of material, from stainless steel to PVC. Some of the popular materials are as follows:

PVC is one of the most common materials for butterfly valves. Some of the qualities of this material are for moderate to low-intensity applications. First, they are lightweight while still possessing impressive structural integrity. Second, they have a wider range of chemical compatibility than most metals.

Cast Iron is a widely used material for butterfly valves. It has considerably more structural strength, integrity, and temperature range to operate in different conditions. Among different other metals, Iron is the inexpensive option. Cast iron butterfly valves are versatile for a wide range of applications.

Stainless Steel is an alloy of Iron, Nickel, and Chromium (minimum 10.5%). The addition of Chromium forms an oxide layer on the surface of the material that protects it from rusting. When the material surface gets any scratch Chromium present in this reacts with Oxygen and makes a protective layer always.

How to operate butterfly valves?

The method of operation of each type of butterfly makes them distinguishable from each other. In the two manual methods, the Handle and gear wheel are there. In the case of automated actuation depending on the model.

Lever operated butterfly valves use a quarter-turn lever usually with a locking mechanism to turn the valve’s stem, to open and close it. this is the simplest form of butterfly valve operation but not so practical for larger valves.

Gear wheel operation is another method common way to operate butterfly valves. In this type of operation, a hand-operated wheel rotates a gear that is attached to the stem to move the disc. This method is useful for all types of butterfly valves either big or small.

The final method of butterfly valve operation is actuation. This is automated opening and closing which is necessary with large diameter butterfly valves. The actuator can only fit on specially made valves that meet certain mounting standards which help to move the disc to open and close.

Advantages of Butterfly valves

Advantages of installing a butterfly valve in the system have different advantages as follows:

- Butterfly Valves are much suitable for large valve applications due to Compact, lightweight design that requires considerably less space, as compared to other valves.

- Due to a quick operational mechanism, it needs less time to open or close.

- The maintenance cost is usually low compared to other valve types.

- A pressure drop across a butterfly valve is small because of its small size.

- Valve with Non-metallic seating can be used in chemical or corrosive media.

- Easy to install and long valve life.

Disadvantage of Butterfly valves

Like every other valve disadvantages of butterfly valves are as follows:

- Throttling is limited to low differential pressure services and that too with a 30- to 80-degree disc opening.

- There is a chance for cavitation and choke as the disk is always in the flow Turbulence flow can affect the disc movement.

- Disc of the valve is always under pressure and can interrupt the flow even when its in open position.

- Sealing function is not much effective.

- Not suitable for high differential pressure.

Difference between Butterfly valve and Gate valve

A few of the main differences between butterfly valve and gate valve are as tabulated below:

| Gate Valve | Butterfly Valve |

|---|---|

| The flow of gate valves is not obstructive in the fully open position. | Butterfly valves provide obstructed flow even in a fully open position. |

| The handling and installation of gate valves are comparatively difficult. | Handling and installation of butterfly valves are quite easy. |

| As gate valves are bigger in size. So, more space is required to install in a piping system. | Due to their smaller size, butterfly valves need less space. |

| Gate valves are suitable for high-pressure applications. | Butterfly valves possess comparatively less pressure withstanding capability. |

| As the gate valve operating time is more, there is less chance of surge. | Due to the quick operation of butterfly valves, there is a possibility of a water hammer. |

| Gate valves possess a longer shaft with difficulty in access. | Butterfly valves have a shorter shaft that is easily accessible. |

| Gate valves are heavy-weight valves. | Due to the smaller size, the weight of butterfly valves is significantly less. |

| Gate valves are quite expensive as compared to butterfly valves. | Butterfly valves are cheaper. |

Butterfly valve Standards

Industrial Butterfly valves are designed based on the following standards of butterfly valve:

- API 609

- MSS SP-67

- BS EN 593

- ISO 5752

- MSS SP-68

- AWWA C504