When the temperature is very low then the normal piping system is not able to hold the processing gases in the form of liquid. Cryogenic piping is the concept of low-temperature piping where material type, support, and valve have different requirements than a normal piping system.

In this article, we will give a briefly described knowledge of the following things:

- What is Cryogenic piping?

- Key challenges of designing cryogenic piping system.

- Material requirement of piping system at different range of temperature.

- Types of Cryogenic insulation.

- Hazards because of Cryogenic liquid.

More to Read: Heat Tracing in Piping: Types, Working, Use, Installation, Comparison (Steam Tracing vs Electrical Tracing)

Table of Contents

What is Cryogenic Piping?

Cryogenic piping refers to a special kind of system that is used in industrial applications which require processing at very low temperatures. Normally around -150°C. Because of this, This much low-temperature material of pipes faces different types of corrosion and deterioration issues.

Cryogenics is part of physics that deal with the property of materials at very low temperature. Very cold and extremely cold temperature changes the chemical and physical properties of materials. Because of this reason, Normally used materials for pipes are not suitable for process application in cryogenic piping.

A process fluid to be called cryogen, Vapor to liquid volume ratio should be 175. Cryogenic Piping is used in many industrial applications including the following:

- Liquid natural gas (LNG) transportation

- Regasification processing

- Many chemical/Petrochemical manufacturing

- Food and beverage production and processing

More Resources: A brief on the Difference between PSV and PRV (PSV vs PRV)

Common Natural Cryogenic material

In general, Cryogenic materials are odorless, tasteless, and colorless when not in liquid states. Cryogenic liquids need to be handled carefully as they cause cold burns and frostbites. In below table, there is a list of some cryogenic liquid temperatures and liquid to gas expansion ratio:

Cryogenic materials are odorless, tasteless, and colorless when vaporized. Cryogenic liquids need to be carefully handled as they may cause skin burns and frostbite. Table-1 below lists down the liquid temperatures and the liquid to the gas expansion ratio of some of the common cryogenic materials:

| Cryogenic Material | Temperature (in liquid state, °C ) | Liquid to Gas Expansion Ratio |

|---|---|---|

| Oxygen | -183 | 1:860 |

| Nitrogen | -196 | 1:696 |

| Methane | -162 | 1:579 |

| Helium | -269 | 1:757 |

| Argon | -186 | 1:847 |

| Hydrogen | -253 | 1:851 |

| Fluorine | -187 | 1:888 |

Key Challenges of Cryogenic Piping Design

Cryogenic piping is a different set of piping items combined together to process for an Industrial application. From Material of pipe to Support type and even types of valve are different in cryogenic piping from Normal process piping.

Design for Fabrication and Installation of Cryogenic Piping must be done with stability to withstand stress and material deformation because of low temperature and thermal forces. Accountability for various constraints like piping layout, space limitations, support location, and Insulation must take into consideration. Some other key challenges for cryogenic piping are as follows:

- Maximization of flexibility and Efficiency: Cryogenic piping system requires specialized innovative and design to maintain a balance and maximization between process efficiency and flexibility. Fabrication of spools for cryogenic piping is crucial for testing of various strength requirements and stress handling capacity by the system.

- Project Cost: Expansion joints and bellows are best to carry the pressure thrust and enough flexibility in processing. But using these entirely will add much more extra cost in total project cost. So, to minimise the project cost and maximize the processing efficiency designing of cryogenic piping should be done carefully to balance need of these flexible bellows and expansion joints.

- Thrust load in Piping System: To stop the gain of heat from environment vaccum jacketed line are used. This has Two layer of pipe travelling concentrically with each other. The inner pipe is called core and carry main Cryogenic fluid while the out pipe provide insulation and support to the core pipe. Because of this combination load of total Piping system increases abruptly. To avoid any kind of failure during processing it is crucial to calculate thrust load to ensure that both inner and outer pipe can withstand buckling and expansion stress with breaking.

- Appropriate Selection of Codes and Standard: ASME B31.3 is the reccomendade code of standard cryogenic piping. But these codes can’t be followed blindly. This requires special consideration with cryogenic lines for material selection, fabrication and testing.

- Piping Support and Valves: Valves used in Cold piping is not having same structure as of normal piping. These valves are specially manufactured in respect with material and strength to sustain in extremely low temperature. For example a cryogenic gate will have a long stem rod for smooth operation. In the same way, Cryogenic line needs to give special attention during its supporting. Cryogenic Support for cold insulation support is made from:

- High Density polyurethane foam

- Phenolic foam insulation

- Polyisocyanurate or PIR

More Resources: Piping Supports as Per Insulation System: Hot insulated, Cold Insulated, Non-Insulated

Cryogenic Piping Materials

Metal shows different properties with different temperatures. Because of that, we can not use the same material type for every range of cryogenic piping. Materials show different properties at different levels of cold temperature because of their crystalline structure, grain size, and heat treatment properties.

Some metals are ductile at room temperature but lose the ductile property when the temperature goes down below its threshold limit. The selection of material as per cryogenic temperature is briefed in further sections.

Properties of Cryogenic material

With the decrease in temperature, the material becomes brittle, and impact test requirements as per codes and standards need to be verified. Various properties required for a cryogenic piping material are as follows:

- Suitability for different fabrication techniques

- Corrosion resistance

- Resistance to oxidation and sulfidation

- Strength & ductility

- Suitable for the cleaning process

- Toughness, resistance to abrasion, erosion, galling, and sizing.

- Physical property characteristics

- Rigidity

- Impact Resistance

Cryogenic Piping Material Suitable for 0°C to -45°C

This temperature range can be found in natural environmental operations. Many industries especially chemical industries process their product in this temperature range. But common construction Steel is not suitable for this range of lower temperatures.

Pipes used for 0°C to -45°C are commonly made of Copper or Nikel alloy with some specified heat treatment as per design requirement. Alloys of Aluminum and titanium are also used for the piping systems at this temperature.

PH steel, i.e. Precipitation Hardening stainless steel is not suitable for operation in this temperature range because of embrittlement and crack development during the process.

Cryogenic Piping material for Temperature up to -75°C

Some steels like low allow, quenched and tempered steels or ferrite nickel steel are suitable for piping operation in this temperature. Most low carbon steel with carbon percentages between 0.20%-0.35% is reliable. Many alloys of manganese, nickel, chromium, molybdenum, and vanadium are suitable for Piping operational work.

Cryogenic Piping material for Temperature up to -100°C

Low carbon steel with 3.5% of nickel is often used in liquid gas storage tank fabrication. This steel can handle temperatures as low as -100°C. Many aluminum, nickel, and titanium alloys are also found to be suitable for pipes at these temperatures. Aluminium 7076-T6 can also be used up to -128°C but not for critical operations.

Cryogenic Piping material for Temperature up to -196°C

Authentic steel of 300 series is most suitable for working effectively in this temperature range. Maraging steel with nickel (20%-25%) with the addition of cobalt, molybdenum, Titanium, Aluminium, and Niobium are also suitable for Piping application at this temperature. All Nickel-based alloys are almost crack-resistant up to -196°C.

Cryogenic Piping Material for temperature below -196°C

This low range of temperature has a special interest for the storage of Hydrogen and Helium. These gases are promising sources of energy for nuclear fusion plants. Among all type of steel only High alloy authentic stainless steel are suitable for these low-temperature ranges. These alloys contain 18%-21% of chromium and 9%-14% of Nickel.

Cryogenic piping Insulation

In the world of piping, insulation has an important role to save heat loss for effective working and processing of the piping systems. To minimize heat leaks from pipes and equipment high-performance materials are required to provide an efficient level of insulation. A good cryogenic insulation effect on the efficiency of fluid processing in Industries and also low maintenance of cryogenic lines

There are mainly 03 types of cryogenic Insulation that are frequently used in Industries:

- Expanded foams

- Gas filled powders and Fibrous materials

- Vacuum Alone or Vacuum Jacketed

Details of each type of cryogenic insulation are described in the following sections.

Expanded foam insulation

This type of insulation is normally considered a mixture of solids and gases with lots of voids. These voids are filled with gases that help to provide a temperature resistance barrier to the pipe or equipment in which this is applied. In this type of insulation heat loss is normally by conduction only as heat loss because convection and radiation are negligible.

Expanded foam insulation is a lightweight, rigid, and closed-cell insulation. this type of insulation is available in several compressive strengths to withstand a load of pipe. Expanded foam insulation has a cellular structure that is formed because of gas intrusion in the foam during manufacturing. Some examples of foam insulation are:

- Polystyrene foam

- Rubber Silica

- Glass foam

The thermal conductivity of insulation foam depends on the gases that are used during the manufacturing process and also on internal radiant heat transfer when foam becomes solid. Because of the closed-cell structure of foam insulation, it provides minimal water absorption and low vapor permanence. Gases that are generally used are CO2 or Freon. Thermal conductivity and density of different materials of expanded foam insulation are as follows:

| Foam Type | Density (Kg/m3) | Thermal conductivity (mW or mK) |

|---|---|---|

| Polyurethane | 11 | 33 |

| Polystyrene | 39 | 33 |

| Rubber | 80 | 36 |

| Silica | 160 | 55 |

| Glass | 140 | 35 |

Advantages of Expanded foam Insulation

- The major advantage of expanded foam insulation is that provides ease of fabrication.

- As the foam is directly blown on vessel on piping to be insulated, This forms a self-supporting base.

- This has a low cost for cryogenic piping insulation compared to other type of insulation.

Disadvantage of expanded foam Insulation

- Gas used for expanded foam forming, i.e. CO2 has lower value of vapor pressure than some of the cryogenic fluids. So, CO2 get condensate in the void that increases heat loss because of conduction.

- Over period of time hydrogen, Helium, and Air diffuses in the foam from atmosphere that reduces its efficiency of Insulation.

- Expansion foams has larger thermal contraction that reduces space between cryogenic pipe and outer atmosphere that causes heat loss.

- When Foam is closely fitted around pipe or equipment, crack can be developed because of difference in shrinkage.

Gas filled powders and fibrous material

The primary method of insulation in gas-filled power or fibrous material is to reduce or eliminate the convection of heat because of the small size of the void within foaming material. A gas-filled power reduces the gas convection as the distance between powder particles in the insulation is much smaller than the gas mean free path.

As a result, the regular gaseous conduction process shifts towards free molecular conduction. This helps to decrease the thermal conductivity. The commonly used insulation material for Gas-filled powder and fibrous material are:

- Fiber glass

- Perlite or Silica powder

- Santocel

- Rockwool

- Vermichlitine

The thermal conductivity and density of the above materials are as follows:

| Material Type | Density (Kg/m3) | Thermal conductivity (mW or mK) |

|---|---|---|

| Perlite | 50 | 26 |

| Silica Aerogel | 80 | 19 |

| Fiberglass | 10 | 25 |

| Rockwool | 160 | 35 |

Advantage of Gas filled powders and Fibrous material

- This has very low thermal conductivity.

- Low density and low particle distribution of material decreases the deformation because of vibration effect.

- Because of finely divided materials solid conduction for heat gets eliminated.

Disadvantage of Gas filled powders and fibrous material

- Requires an additional layer of vapor barrier as moisture and air diffuses in the finely divided material.

- Filled gas must be unreactive and compatible to powder material.

- With time powder tends to settle because of which vibration and heat loss from upper circumference of pipe started.

Vacuum Jacketed Insulation

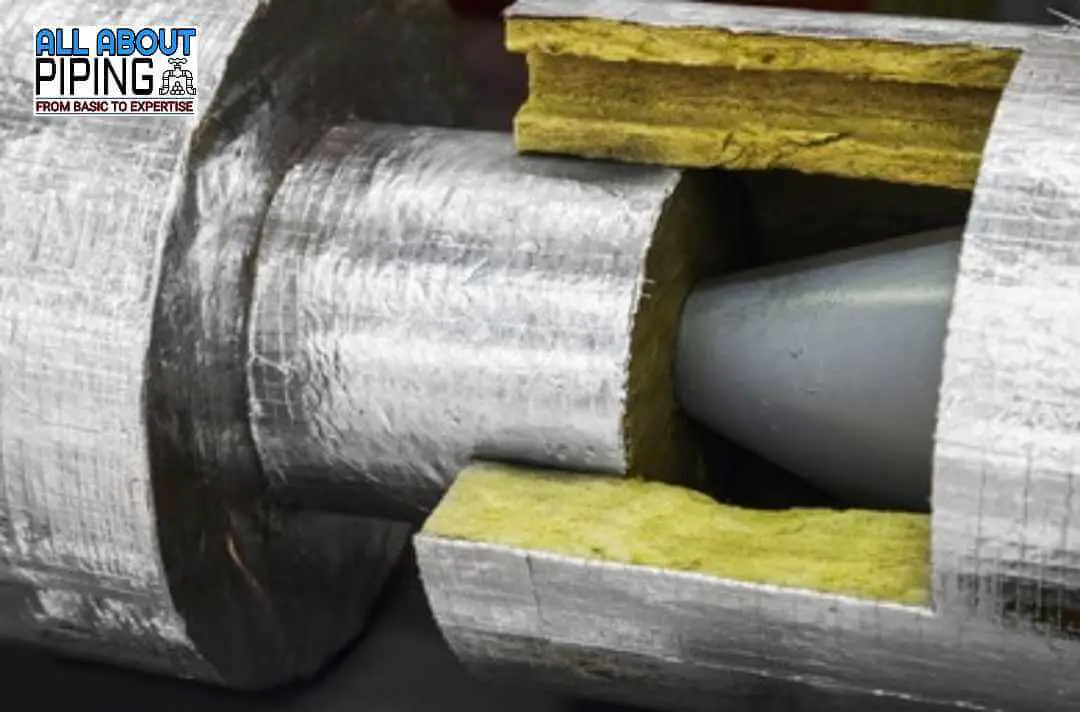

Vacuum jacketed cryogenic insulation is just like steam jacket piping where there are 02 concentric parallel pipes running together. The inner pipe is called the core while the outer pipe is called the jacket. The Vacuum jacketed insulation is the most effective cryogenic piping method for insulation in terms of safety, reliability, and durability of cryogenic fluid transfer.

A well-designed vacuum jacketed insulation for a cryogenic piping system includes the following accessories to control the flow of fluid, efficient connection, and maintain the vacuum space.

- Vacuum Jacketed Pipe

- Flexible Lines

- Vacuum Jacketed Valves

- Bayonet Connections

- Vacuum Valves and Operators

- Vapor Vents

- Vapor Vent Heaters

- Vacuum Jacketed Manifolds

In the vacuum jacketed Cryogenic insulation inner pipe that carries the cryogenic fluid is wrapped with multiple layers of super insulation materials. The insulating layer is made up of radiant heat barrier material and non-conductive spacer material and the space between the two lines is evacuated. there are two types of vacuum jacketed insulation:

- Rigid vacuum jacket and

- Flexible vacuum jacket

Advantage of Vacuum jacket insulation

- Significant reduction in loss of liquid cryogen caused by heat leaks.

- Virtually no decrease in thermal performance of vacuum jacketed pipe over time.

- Rigid vacuum jacketed pipe requires very less maintenance in long duration.

- Longest life cycle insulation and insulating material.

- Improved process safety due to elimination of frosty and dripping conditions.

Disadvantage of Vacuum jacket insulation

- Need much more initial investment for installation.

- Need highly skilled workers to installation and inspection.

- Replacement or maintenance cost is high

More Resources: SOP for jacketed piping: Types, General requirement, Fabrication, Erection, Testing

Cryogenic Pipe Sizing

An accurate size for cryogenic service is an important factor for saving the complete piping system from thermal force and heat loss. You can simply understand by this example: “If the size of a pipe is bigger than its surface area will be more and heat loss per unit area will be more and its other terms, if the size will be less than the required size for precessing than excessive hoop stress, will be there on the pipe that can reduce the lifespan of the piping system.

Choosing an exact pipe size for cryogenic piping normally depends on 04 factors:

- Flow Requirement of Piping System: this is determined by how much liquid is required for process the system at the end. The amount of liquid required to maintain the cycle of processing and distance between two processing equipment decides the required flow rate and hence pipe size.

- Operating System pressure: Pressure of the cryogenic system directly related to amount of liquid flow through it. Apart from the flow rate operating pressure also has a dependency on the type of end equipments it is connected with.

- Equipments Connected with Piping system: In a piping sytem minimum and maximum operating pressure depends on the type of equipment it is connected with. For example if some line connected with pump at one end and storage tank at another end than its obious to have greater pressure at pump side than that of tank side. This factor allows to have different size of pipe on different ends.

- System Restrictions: System restriction mean the points on a piping system where, there is a chance of pressure drop like elbow, orifice flange, strainer etc. This pressure drop can effect the liquid flow rate in the processing system that will ultimately effect processing cycle. Size of pipe is always considered with these pressure drop not only in case of cryogenic piping but in all type of piping system.

Safety Hazards with Cryogenic Piping system

Working in extremely low temperatures has many different hazards like a cold burn, Skin freezing. Some of the cryogenic hazards are as follows:

- Brief exposure in cryogen liquids can damage delicate tissue like eyes.

- Skin when not protect can stick to the metal surface in contact and can get tear away when pulled. This can happen even with non-metallic surfaces.

- Cryogenic liquid and cold vapours can cause thermal burn injuries.

- Flammable cryogenic gases like H2 can burn or explode.

- Without adequet venting or pressure relife device on container enoumorous pressure can buildup which can cause explosion.

Conclusion

Cryogenics is a branch of physic that deal with change in the chemical or physical property of material because of very low or extremely low temperature. So, the material used for cryogenic piping could not be the same as normal piping. Even types of support, Insulation, and valve are different from general piping.

Some of the key points of the article are as follows:

- Cryogenic equipment and piping needs to be insulated to minimize all types of heat transfer.

- Piping material selection should be done according to working temperature of cryogenic fluid.

- Expanded foam insulation has lower density and cellular structure but this increases solid conduction.

- A gas filled powder and fibrous material decreases the gas convection because of smaller size of voids.

- Filled gas to “Gas filled powder” should be chemically neutral to power.

- Vaccum Jacket Insulation is the most effective way to maintain the temperature but its cost too and can increase budget drastically.