When was the last time you closed a tap?

Maybe, just a few minutes ago. Well, that is a valve. Obviously, that is an industrial valve but the function of all valve are basically the same, i.e. either to Isolate or regulate the flow. Valves are of many kinds and their use is too versatile which depends on fluid flowing through that pipe, its cost, and type of flow regulation required.

In this article, we will learn:

- What is a valve and why it is important for a piping system?

- What are the types of valve and their symbols?

- What are the criteria for choosing a perfect valve for a piping system?

- What are common types of valves used in industries?

- Codes and standards followed during manufacturing of valve.

Table of Contents

What is Valve?

Valves are a mechanical device that controls the flow and pressure in a piping system. They are one of the most essential components of a piping system that control and convey liquids, gases, vapors, slurries, etc.

Valves can be defined as:

A device or Natural object that can regulate, direct or control the flow of fluid by opening, closing, partially closing, or obstructing passageways.

Technically valve falls under the category of Piping fittings but its use and scope is so diversified that it has a separate category for codes of manufacturing and installation.

A valve is a device or natural object that regulates, directs, or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically fittings but are usually discussed as a separate category. Valves can be either: 1. Manual operated 2. Motor operated 3. Both manual and motor operated.

The simplest valves are equipped with one way flap mechanism that allows flow in one direction only. Valves can also work through variable pressure or temperature and maybe run by a motor and operated manually. Manual valves manufactured with levers, pedals, hand knobs, or wheels that help to operate that valve for the purpose required. A valve sometimes can be geared mechanically that controls the valve ball or disc.

What is the Role of a valve in Piping System?

For a piping system to control fluid flow, Regulate fluid pressure, precise the ratio of any mixture, or taking a sample of any product valves are widely used in any industry. In a general sense, valves restrict, stop and control the flow of fluid in a piping system. In-depth, valves are installed in a piping system to:

- controls and regulate loss or gain of temperature from a piping system.

- Redirects the flow from one direction to another as per the requirement of the piping system.

- Restrict the flow for system balance and over pressurizing.

- Prevent reverse flow of fluid in a one-way fluid flow system.

- Stop the flow of gases or liquids if any system failure appears.

With such an important role in increasing efficiency, controlling quality measures of product, improving safety measures, and keeping system running, valves are still rarely discussed during the planning of construction of project or processing. Out of many, one basic reason can be its smallest cost of the total project.

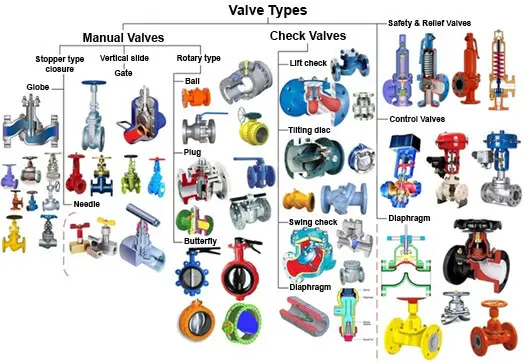

What are the types of valves in Piping?

In a piping system, according to the purpose and required different types of valves. The cost of valves in any piping system is up to 20%-25% of the overall piping cost. There are different type of valves used in industries for many different purposes:

- Gate Valve (commonly used)

- Globe Valve (commonly used)

- Check Valve/Non-return valve (commonly used)

- Plug valve

- Ball Valve (commonly used)

- Butterfly Valve

- Needle Valve

- Pinch Valve

- Piston valve

- Pressure Relief Valve

- Pressure control valve

- Diaphragm valves

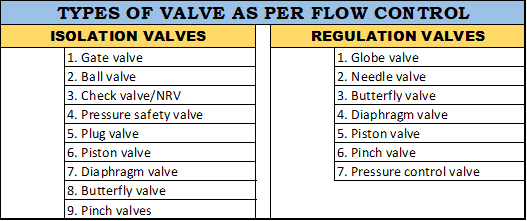

Valve classification according to flow control

Above mentioned valve types fall under two category according to the requirement of flow control:

Isolation valves

This type of valve either completely restricts fluid flow or allows it. This type of valve can’t be operated in partial open or closed condition. In the case of the regular partial opening, the valve disc can damage and leads to an unwanted occurrence. valves falling in this category are:

- Gate valve

- Ball valve

- Check valve/NRV

- Pressure safety valve

- Plug valve

- Piston valve

- Diaphragm valve

- Butterfly valve

- Pinch valves

Regulation valves

These valves help us to regulate pressure and fluid flow in whatever required precision. They can efficiently be operated in partial open or close conditions. design and construction of these valves make it possible to withstand in partial condition too with long term operation.

- Globe valve

- Needle valve

- Butterfly valve

- Diaphragm valve

- Piston valve

- Pinch valve

- Pressure control valve

Some valves having multiple functionalities falls in both the category and can be used for both purposes.

Classification of valves as per End connection

When valves are installed in a piping system, they are connected with different types of end connections. As per these type of connection, valves are classified as:

- Screwed End valves

- Socket end valves

- Flanged end valves

- Butt weld valves

- Wafer type valves

- Buttress end valves

How to Choose valve type?

As we have learned till now different valves have different purposes of operation and cost. For any piping system choosing a perfectly suitable valve in terms of operation, the cost is the most important thing. Valve type selection is always done with certain conditions like:

- Required Functions

- Fluid service condition and characteristics

- Frequency of operation

- Isolation of regulation requirements

- Environmental conditions

- Past experience in a similar situation

- Maintenance requirements

- Size and weight of the valve

- Cost of an alternate suitable valve

Let’s know the effect of each selection criteria on choosing a perfect valve of a piping system.

1. Function Requirements

In a piping system, it is most important to analyze the functionality of the system. According to that only we can choose a perfect valve for it. Functions required can be any of these:

- complete Isolation of fluid flow

- Regulation flow required

- Uni-direction flow requirement

- Bi-directional flow of fluid

- Change of direction of fluid flow

2. Fluid Service condition and characteristics

The characteristics and condition of a fluid flowing inside a piping system must be carefully defined as this is a significant factor for choosing a valve for the system. For example:

- Any clean services like air, water allows a wide variety of valves to choose from.

- A dirty service piping system that generally has suspended solid particles requires special attention to valve selection.

- Fluid service containing abrasive and erosive material.

- Fouling or scaling service which creates a deposition of material on the inside layer of a pipe system.

- Slurries

- Hazardous and corrosive services.

- Vacuum or high-pressure services

- Cryogenic or high-temperature piping system.

3. Frequency of operation

Piping systems with a frequent requirement of valve operation should take into account the fact that shut off capability will likely deteriorate valve disc and other fittings of the valve. So, it is necessary to ensure enough isolation withstand in frequent operation conditions. Most of the isolation valve doesn’t operate so frequently but some valve of a regenerative system need to operate frequently. If the operation will be frequent then the required operating force and time will increase, and hence, deterioration of valve components.

4. Isolation and Regulation Requirements

Among the above, all mentioned valve types, very few types of valves are there which can efficiently shut-off over a significant period, and frequency si reduced further if the working fluid is either gas or contains abrasive material. While designing a piping system these criteria should take into account for the selection of valves.

The need for interference in a live system requires a perfect leakproof tightness system for valves. Shut down valves are not so frequently required to shut off and is often acceptable with a tolerable amount of leak.

5. Environmental conditions

The local environment in which the piping system runs plays an important role in the selection of valve or piping material. If the environment nature has flammable, toxic, or deteriorating properties then the material valve required will be quite different from valves of normal condition.

6. Past experience in Similar conditions

A comparison should be always there while constructing a similar pipe system or upgrading it. Past experience either good or bad will play a vital role in valve selection. Sometimes local expectations and experiences can condition the piping system for more efficient use.

7. Maintenance requirements

The location, weight, size, frequency of use, and environmental condition plays a specific role towards the requirement of maintenance of valves and hence selection of valve too.

8. Size and weight of the valve

Even the size and weight of the valve don’t such an important role in the valve selection procedure but for some special cases like onshore construction or much-elevated position valve size and weight must keep in mind for construction purpose.

9. Cost of an alternate suitable valve

For this selection criteria, valve life cost must be also considered not just purchase cost at the time. Sometimes higher purchase cost valves seem to be cheaper while looking for the whole life value of that. Alternate suitable valve type also affects the cost in valve selection procedure as a Ball valve and butterfly valve have also the same functionality but huge difference in cost.

Codes and Standards for valves in Piping

As for every piping component, Valves comes with their own codes and standards that valve manufacturing company need to understand well. In this section of the article, we will give you a brief about the code and standard of the valve. (this may not cover all detailed requirements for some specific service).

The typical codes for piping used in valve industries (except water industries) are ASME B31.1 for Power Piping, ASME B31.3 for Process Piping, ASME B31.4 for the pipeline transportation system, ASME B31.8 for gas transmission and distributions system. In every code of piping or pipeline, there is a specific table or sections for valves.

This is the responsibility of the piping system designer to recommend the most appropriate design for the service and conditions. Most of the time valve manufacturer is unaware of the actual service and conditions of the piping system. Therefore, it is a must for the designer of the piping system that they clearly understand the requirement of valve specification with respect to pressure or temperature.

Although there are always some exceptions, you may be encountered with some cases which require special attention as there is no details available in codes of piping. This type of exception can be very few and examined on a case-to-case basis.

ASME B31.1 for Valves

The ASME B31.1 code describes 03 valve standards except for cast iron and bronze valve. The standards covered in this code are:

- ASME B16.34: Valves with threaded, flanged, and weld end connections

- MSS SP67: Specifies standards for butterfly valves

- MSS SP68: give details about the high-pressure butterfly valve. Such a high-pressure valve should be pressure tested as per piping system operating and design pressure.

ASME B31.3 for valves

This ASME B31.3 code defines 04 valves excluding cast iron and bronze valves. The standards for the valve in this code is as follows:

- ASME B16.34: Valves with threaded, flanged, and weld end connections

- MSS SP72: defines Ball valves with flanged or butt weld joints for general services.

- API 608: this gives details about metallic ball valves with flange end connections.

- API 6D: Give specification for pipeline and piping valves

ASME B31.4 for valves

This code of Valve standards provide details about 08 valves and again excluding cast iron and bronze valves. These valve standards, which are more comprehensive than the previous codes, are:

- ASME B16.34: Valves–Flanged, Threaded, and Welding End

- MSS SP68: High-Pressure Butterfly Valves with Offset Design

- MSS SP72: Ball Valves with Flanged or Butt-Welding Ends for General Service

- API 600: Steel Gate Valves-Flanged and Butt-Welding Ends, Bolted Bonnets, Twelfth Edition

- API 602: Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries

- API 603: Corrosion-resistant, Bolted Bonnet Gate Valves-Flanged, and Butt-Welding Ends

- API 6D: Specification for Pipeline and Piping Valves

- API 6A: Specification for Wellhead and Christmas Tree Equipment

ASME B31.8 for valves

The ASME B31.8 code lists 05 valve standards, excluding cast iron and thermoplastic valves. These standards are:

- ASME B16.33: Manually Operated Metallic Gas Valves for Use in Gas Piping Systems up to 175 psi (Sizes NPS1/2 Through NPS 2)

- ASME B16.34: Valves with Flanged, Threaded, and Welding End

- ASME B16.38: Large Metallic Valves for Gas Distribution: Manually Operated, from DN 65 to DN 300 with a pressure range of a maximum of 125 psi (8.6 bar)

- API 6D: Specification for Pipeline and Piping Valves

- API 6A: Specification for Wellhead and Christmas Tree Equipment

Conclusion

To conclude, Even Valves sharing the least budget in the total project cost valves are one of the most critical items that need special attention while designing a piping system. The role of a valve in piping is not just limited to regulation or isolation of fluid flow but this also helps in balancing the whole system. For the different purpose, there are different kind of valves which has furthermore variation as per conditions and requirement of the system.

Choosing the most suitable valve for any piping system takes great effort by the designer as they have to take care of all conditions from environments to costs. For a similar condition of construction getting info about past experiences can help to choose better.

Codes and standard of valves help us to select the best suitable but there is always an exception which needs to discuss on case to case basis for proper resolution for piping system requirements.

You can download a Pdf on “Overview on Valves” written by “Mostafa Mahmoud” for your knowledge and reference.