In some piping systems, depending on the nature of fluid automatic isolation of fluid flow is required. As for piping Professionals, we all must know this type of electrically operated valve for a better understanding of its role in the piping system. In this article, we will try to give you a brief info about solenoid valves. Here you will learn about:

- What are solenoid valves?

- Symbols and terminology of solenoid valves

- Types of solenoid valves

- The basic design and working principle of solenoid valves

- Features and uses of solenoid valves

More to Read: What is the Role of a valve in Piping? Type of Valves in Piping.

Table of Contents

What is Solenoid Valve?

Solenoid valves are electromechanically activated valves, used to control the flow rate or direction of the fluid. It can be used in both pneumatic and hydraulic ways to regulate fluid flow. These electrically activated solenoid-operated valves are typically used to control the flow and direction of flow in the system. The spool connected to the valve connects a ferrous metal plunger which is typically spring-centered.

The plunger slides within a core tube of non-ferrous metal which is surrounded by a coil of electrical windings. the Solenoid coil exists with any range of solenoid valve voltage from the range 12-48 VDC to 110-220 VAC. When the coil is being charged with electricity a magnetic field is created which pushes or pulls the plunger.

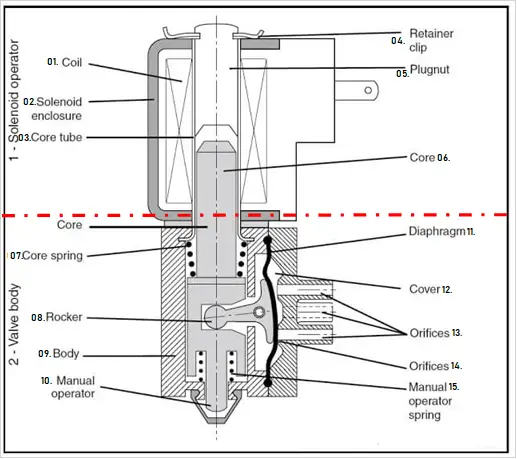

Parts of Solenoid valves

There are some terms and names of parts of a solenoid valve that you must know. From the above solenoid valve diagram according to marked serial numbers each solenoid valve part are described below:

- Coil: This is the electrical part of the valve consisting of a wound of the insulated copper wire creating a magnetic flux when energized. This coil is placed on the tube with retaining clips.

- Solenoid Enclosure: Metal housing around the coil for electrical or mechanical protection is call solenoid enclosure. This protects the coil against the entrance of water or duct.

- Core Tube: Stainless steel tube that is closed at one end is installed to improve the magnetic flux of the coil upon energization.

- Retainer Clip: This is the clip anchoring the coil to the YOKE.

- Plugnut: This is the stationary part of the solenoid valve that helps to press the core tube in the closed-end to improve magnetic flux.

- Core: This is the soft magnetic plunger part of the valve that moves by magnetic force.

- Core Spring: This is a retractable part of the Solenoid valve which helps the core to keep in a fixed position when the coil is not energized.

- Rocker: This is the moving part serving to open and close the ORIFICE for the passage of fluid.

- Body: This is the main part of the valve with all ports and main seats fitted inside it.

- Manual Operator: This for the manual operation of the solenoid valve to open or close the orifice. This acts as a solenoid valve manual override button to control the flow.

- Diaphragm: This is isolating the fluid from the control system with help of seal-tight assembly.

- Cover: This is mounted on the valve body and incorporating a number of Orifices.

- Orifice: This is the flow path of fluid transmission in the valve body.

- Manual Operator Spring: This is actually the part of the Solenoid valve that helps to ensure the drawback of the spring to its initial position.

Featured Post: What is the Coriolis flow meter and how this works?

Symbols of Solenoid valves

The symbol for the Solenoid valve is depicted below. This also can be considered as a solenoid valve symbol is just like the symbol of a gate valve with the letter “S”.

Types of Solenoid valves according to flow control

There are mainly 02 different types of Solenoid valves according to flow control:

- Direct Acting Solenoid valve

- Piolet operated

Details of each type are described following sections.

Direct Acting Solenoid Valve

This type of solenoid valve has a coil that magnetically opens the valve in a direct action resulting in the core and seat of the to shift. Direct-acting solenoid valves use to energize the magnetic field of the solenoid to operate.

In a normally closed direct acting solenoid valve, The flow towards the outlet port is blocked when no electric current is applied to the coil. When no current is applied, Spring presses the plunger on the valve seat. Current through the plunger generates a force that pulls it and seals against the spring force. In such condition, the Path of flow is open and process fluid start to be transported through the direct-acting solenoid control valve.

Main Features of a direct-acting solenoid valve

- The sealing element of the valve is directly connected to the core.

- This type doesn’t need differential pressure to open.

- The maximum pressure difference across the valve is limited by the magnetic force of the used coil and the seat diameter. This acts as a solenoid valve with a limit switch.

- This valve is commonly used for low flow volumes.

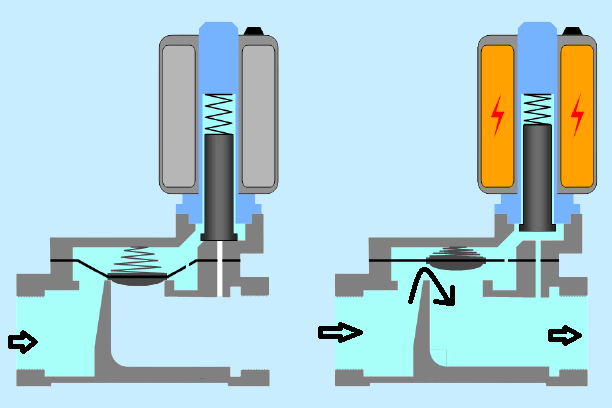

Pilot Operated Solenoid Valve

In the Pilot solenoid valve, the plunger act according to differential pressure. Pilot-operated directional control valves require less electrical energy to work to keep up full power with specific flow control. This type of valve performs at a slower rate than a direct-acting solenoid valve.

This uses a solenoid diaphragm for flow control with pilot control using a small chamber directly above the diaphragm that helps in the operation of the valve. Process fluid is allowed to enter the chamber through a small orifice that compresses against the diaphragm and forces the seat to maintain the closing seal.

Once current is applied to the pilot solenoid, the diaphragm is being pulled upwards against the spring force. The process fluid in the chamber is forced back through the orifice towards the inlet port where it merges with the main flow through the vale body.

Main Features of Pilot Operated Solenoid Valve

- The valve is sealed by the diaphragm.

- It utilizes the energy of the streaming fluid to open and close.

- This type of valve needs opening and closing with minimal differential pressure known as “minimum working pressure”. This pressure varies from 0.1 to 1 bar, depending on the dimension of the valve.

- The same size of the coil can be used for the operation of valves with different dimensions because the diameter of the pilot seat remains the same for different dimensions of valves

- The flow direction for the valve is given.

More resources: What is Triple Offset Butterfly Valve? Definition, Design, Application, Code, and standard

Difference between Direct Acting and Pilot operated Solenoid valve

The major difference between direct-acting valve and pilot-operated valves are as follows:

| SL. NO. | DIRECT ACTING SOLENOID VALVE | PILOT OPERATED SOLENOID VALVE |

|---|---|---|

| 01 | Have direct connection with opening and closing with armature | Differential pressure of process fluid directs armature for opening and closing |

| 02 | This doesn't use a diaphragm | Diaphragm is bieng used for flow control |

| 03 | Can work with negative pressure circuit | Only works with Positive differential pressure |

| 04 | Highly responsive with very less reaction time | Respectively takes moore time to response |

| 05 | Low flow capacity with CV value below 01 | Higher flow capacity, CV value can reach upto 03 and Above |

| 06 | Higher power consumption | Lower power consumption |

| 07 | Working efficiency doen't compromise with purity of flow medium | Require high purity of flow medium |

Types of a Solenoid valve according to the flow distribution

In a solenoid control valve, we can direct the process fluid as per our requirement. This flow distribution can be done as per the number of ports required for distribution. According to flow distribution criteria solenoid valves are of 03 types:

- 2 way solenoid valve

- 3 way solenoid valve and

- 4 way solenoid valve

All details of each type of flow distribution valve are as described:

2 way Solenoid Valves

This is the most common type of solenoid valve used in industries. A two-way valve has two ports that allow flow to control either the open or close position. A two-way solenoid valve can be “Normally open” or “Normally closed” in its operation.

A 2-way solenoid valve has one orifice path of flow which can be worked from both directions. The bi-direction nature of solenoid valves makes them more efficient and productive.

A “Solenoid normally open valve” remains open until current is applied to the coil to close the valve, while the “Solenoid normally closed valve” remains close until a power source causes it to open. A two-way operated solenoid valve has two ports (inlet and outlet) and two positions (open and close)

Features of Two way solenoid valve

- This valve doesn’t depend on differential pressure to perform the open or close operations.

- Kind of automatically operatable depends on its type of “Normally open” or “Normally close”.

- Quick and easy for controlling fluid flow.

- This can act s a bidirectional valve.

3 way Solenoid Valves

A 3-way solenoid valve has also two types. i.e. 1) Normally open and 2) Normally closed.

A three-way solenoid valve has 03 pipes connected (Cavity port, Body orifice port and Stop port) to this and has 02 orifices, the body orifice, and stop orifice. One of these orifices is always open to provide flow for process fluid.

The 02 orifice in 3 way solenoid valve creates 02 paths of fluid flow. When power is shut, the plunger of this valve raises which seals off the stop orifice and opens up the body orifice allowing flow through the body orifice port.

While the opening of the stop orifice allows flow through the valve from the cavity port and exists from the stop port of the valve.

In the case of a 3-way Solenoid valve Normally open, When power is off, a plunger is raised to seal off the stop orifice while in the Solenoid valve normally closed, when power is connected plunger is getting down and seals the body orifice

Features of 3 way solenoid valve

- This has two orifices with two paths of flow.

- Useful where a mixing media is required for two types of fluid.

- Electrically operated and don’t depend on differential pressure.

- Easy to install and operate.

4 way solenoid valve

4-way solenoid valves offer more operational versatility as they can be used for anything. A 4-way solenoid valve actually has 05 ports. A 4-way solenoid valve has four pipe connections. 1) one pressure inlet 2) two-cylinder ports and 3) One or two outlet ports.

These valves are required for double-acting cylinders because they actually switch the direction of airflow from going in the bottom of the cylinder inlet to going in the top of the cylinder’s other port. This helps the cylinder to open and close very rapidly. This type of valve is much more useful when different types of fluid are mixed with each other in a certain fixed ratio.

Features of 4-way solenoid valve

- Allows a higher flow rate through the valve.

- Can be used with Single-Acting Cylinders with or without an air hole because the air can escape back through the solenoid and out the exhaust port (if open).

- Allow you to control the outlet flow rate.

Solenoid valve basic design & function

Solenoid valves have a control unit which is when electrically energized or de-energized this acts either to shut off or allows fluid flow. The actuator of a solenoid valve acts as an electromagnet. When energized, a magnetic field is generated which pulls the plunger against the action of the spring while the de-energized plunger returns to its original position.

The basic design of a solenoid valve can be divided into two categories:

- Solenoid Operator and

- Valve body part

The solenoid Operator part of the valve is basically an electrical circuit that helps to move the plunger of the valve by generating a magnetic field when an electrical current is passing through this. There are basically 06 parts of this complete circuit

- Core

- Solenoid Coil

- Solenoid encloser

- Core tube

- Plugnut and

- Retainer clip

The valve body is basically the operation part of the valve that controls the fluid flow according to the application of electrical current in the solenoid operator. This part of the valve contains 08 sections to act together for flow control

- Rocker

- Core

- Core spring

- Manual operator

- Diaphragm

- cover

- Orifice and

- Manual Operator spring

The function of each part is covered in the above section (Parts Name and Terminology for Solenoid valves) of this article.

How does Solenoid Valve work?

As discussed earlier in this article, A solenoid valve has two main components: Solenoid and Valve Body. A solenoid has an electromagnetically inductive coil around its iron core at the center. At rest, it can be normally open (NO) or Normally Closed (NC). In a de-energized condition, a normally open valve is open for fluid flow while a normally closed valve restricts the flow of fluid.

When current passes through the solenoid, the coil gets energized and creates a magnetic field which creates an attraction with the plunger and moves it overcoming the spring force. If the valve is normally open, the plunger moves downward to close the flow and it is Normally Close then the plunger moves upward to allow fluid flow.

Advantages and Disadvantages of Solenoid valves

Solenoid valves are used in every industry due to their versatility of this valve. The solenoid valve can be used for either Liquid or gas transportation in the piping system. Its electromechanical magnetic nature makes the valve a reliable option for pneumatic and hydraulic systems.

Advantages of the Solenoid valve

Solenoid valves have a large number of advantages that are gained by improved design over the years that makes the valve safer and efficient. The solenoid valve can adapt and be installed in a number of locations making the valve versatile for many applications. some advantages of solenoid valve are as described below:

- Quick responsive

- Low power consumption

- Remote operation

- Fits in a variety of machinery and applications

- Cheap replacement parts

- Compatible with both AC and DC power supply

- Low and High-temperature usage

- Safety external leakage block

- Can be installed vertically or horizontally

Disadvantages of the Solenoid valve

Like every other valve solenoid valve also have some disadvantages that make this valve with some error. disadvantages of solenoid valve are as follows:

- Sensitive to voltage change

- The valve can partly close if the magnetic field isn’t set up correctly

- The coil may need to be replaced over the lifetime of the valve

- Control signal must stay on during operation

- Valve fluid can be affected by the flow (pre-valve flow is always greater than the backflow of the valve)

Common uses of Solenoid Valves

Some common domestic and Industrial uses of Solenoid valve includes the following:

- Refrigeration systems use solenoid valves to reverse the flow of refrigerants. This helps in cooling during summer and heating during winter.

- Irrigation systems use solenoid valves with automatic control.

- Dishwashers and washing machines use solenoid valves to control the flow of water.

- Air conditioning systems use solenoid valves to control air pressure.

- Solenoid valves are used in automatic locking systems for door locks.

- Medical and dental equipment use solenoid valves to control the flow, direction, and pressure of the fluid.

- Water tanks use solenoid valves to control the inflow or outflow of water, often in combination with a float switch.

- Car washes to control the water and soap flow.

- Industrial cleaning equipment

Special features of Solenoid Valves

- Electric power reduction: A small current pulse is enough to open or close the valve and the electric power is reduced far enough to hold it in position. This helps in conserving energy.

- Latching: The latching or pulse coil version provides a solution for applications with low-frequency switching also. The valve is energized by a small electric pulse to move the plunger up or down. A permanent magnet is used to keep the plunger in that position with no additional spring or magnetic field. This lowers the consumption of power and heat development in the valve.

- High Pressure: High-pressure versions are designed for pressure requirements up to 250 bar.

- Manual override: The optional manual override feature provides better safety and convenience during commissioning, testing, maintenance, and in case of a power failure. In some type of valve, this cannot electrically actuate when the manual control is locked.

- Media separation: Media separation design allows isolation of the media from the valve’s working parts, making it a good solution for aggressive or slightly contaminated media.

- Vacuum: Valves that do not require a minimum pressure differential to become operatable for rough vacuums. Universal direct-acting or semi-direct acting solenoid valves are well suited for applications in vacuum conditions of the piping systems.

- Adjustable response time: The time it takes the valve to open or close can be adjusted, just by rotating screws on the valve’s body. This feature can help prevent a water hammer in the piping system.

- Position feedback: The switching status of a solenoid valve can be indicated with electrical or optical position feedback.

- Low noise: Valves have a damped design to reduce the noise during the closing of the valve.

Selection Criteria of Solenoid Valve

This is must to understood before going to design a piping system with a solenoid valve that which type of valve will be applicable on that certain condition to work it most efficiently. Selection criteria of solenoid valves are as follows:

Type of Solenoid valve: This can be determined according to fluid flow requirement whether that piping system requires and two-way or three-way solenoid valve.

Applicable Voltage: Solenoid valves are generally AC or DC power operated. So, this must keep in mind, the power availability and requirement while choosing for valve type.

The pressure of Piping System: Chosen valve must withstand the high pressure of the line this is equally important to look for a minimum pressure of the line too as pressure difference can cause valve failure.

Temperature: This si must ensure that valve material will sustain the temperature of the fluid flowing through a piping system. Temperature consideration is also important to the operational efficiency of the valve with respect to the viscosity of the fluid.

Valve Body material: Before choosing an appropriate valve body material based on the chemical properties and temperature of the fluid and corrosive nature of the environment.

Seal material: Seal material should be selected based on the chemical properties and temperature of the fluid flowing through the piping system. NBR, EPDM, FKM (Viton), and PTFE (Teflon) are common options to choose from.

Required Valve Function: Depending on the operational period, it is a must choose from a normally open or normally closed valve. If the opening time is longer than the closing time then a normally open valve will be more appropriate and vice versa.

Operation Time: It is essential to determine if the installed valve will require a direct, indirect, or semi-direct solenoid valve.

Response Time: The response time of the valve is required to determine if the valve is required to quick isolation or not. And if quick isolation is required then how much time is there for isolation.

Approvals for solenoid valve: Ensure that the valve is appropriately depending upon the application of the valve.

Conclusion

A quick note on the go for solenoid valve are as follows:

- Solenoid valves are electromechanically activated valves.

- This can be operated for a clean liquid or gas piping system.

- Indirect solenoid valves are required differential pressure to become operatable.

- Solenoid valves can be of two or more inlets or outlets as per requirement.

- There is 02 type of Solenoid Valves as per flow control: 1. Direct-acting 2. Pilot operated.

- 03 types of solenoid valves as per flow distribution: 1. 2-way 2. 3-way and 3. 4-way solenoid valves

- Normally open (NO) and Normally closed (NC) are types of the valve according to the requirement of operational time of the valve.

- Solenoid valves are sensitive to voltage fluctuation.