Measuring fluid flow is much important for the fact of knowing its volume, density of the fluid, Mass flow rate, and many more variables to calculate. A Coriolis flow meters is a measuring device that provides us real-time data about all properties of the fluid flowing through pipes for its measurement and control.

A mass flow meter never measures the volume of fluid but it measures the Mass of fluid per unit time. And volume is calculated based on the density of the fluid. If fluid has variable density then establishing a relationship of measurement won’t be simple.

The Density of fluid may change with temperature, pressure, and composition. Fluid can also be a combination of phases. So, actual density is determined by a specialized piping component call “Mass flow meter”.

Coriolis Flowmeter is a type of Mass flow meter that measures gas and liquid flow in the pipe with more accuracy. Here in this Article “Coriolis flow meter” you will learn the following:

- What are the Coriolis flowmeter and Coriolis flow meter working Principles?

- Component of Coriolis flow meter for mass flow measurement.

- What can we measure with this?

- Advantages and Disadvantages.

- Use and Application.

More to read: What is a solenoid valve? How does the Solenoid valve work?

Table of Contents

What is Coriolis Effect?

To know what is Coriolis flow meter and Coriolis flow meter working principle is, We have to know about Coriolis Effect that is Invented by Gaspard-Gustave de Coriolis. To understand what the Coriolis effect is we will take a simple example:

Just Consider that You and your friend traveling in 02 different car with a speed of 110Kmph and Your friend ask you to throw a bottle of beer towards him. You pointed to your friend’s position and throw that bottle but things didn’t go as it is planned.

That beer bottle falls slightly backward to its aimed location. Do you know why??

Well, that is the Coriolis effect. This Explains When Some object is not firmly connected to the ground and traveling from one point to another point then there is slight deflection observed on its path with respect to things rigidly connected to the ground. This deflection is because of the inertia of that object in motion.

What is a Coriolis Flowmeter?

A Coriolis flow meter is a type of mass flow meter designed specially to measure the different variables of fluid flow through its mass and inertia. This is one of the most versatile flow meters available.

One of the main features of the Coriolis flow meter is, It can measure mass flow, density, and temperature in the same device with help of Coriolis technology. Sometimes a Coriolis flowmeter is also known as an Inertial flow meter.

Featured Article: Vacuum Ejector System: Purpose, Selection, Working, Advantages

Components of Coriolis Flowmeter

The main components of the Coriolis flowmeter that make it enable for taking measurements and fulfilling Coriolis flowmeter installation requirements are as follows:

- Flow Tube: This Tube inside Coriolis mass flowmeter carries fluid from its inlet point to the outlet point. Variation in the Oscillation frequency of this tube generates a relationship to measure Volume, Density, and Velocity of fluid flow. There is a total of 02 tubes in a Coriolis mass meter.

- Inlet Coriolis Pickoff Sensor: This Coriolis flow Sensor on the inlet side of the Flow tube takes the measurement of frequency and generates Sine-curve.

- Outlet Coriolis Pickoff Sensor: Like Inlet Pickoff Coriolis sensor, Outlet pickoff sensor installed on Outlet leg of the flow tube. The difference recorded of both Sine-Curve creates a relationship to give a measurement for Coriolis effect flow meter.

- Drive Coil or Magnet: This is a driving unit of the Mass flow meter that keeps oscillating the flow tube.

- Resistance Temperature Detector (RTD): An RTD is a temperature sensor that measures temperature using the principle that the resistance of a metal changes with temperature.

- Case: This is a protective metallic layer of the Coriolis meter.

Coriolis flow meter working principle with animation

A Coriolis type flow meter is consists of 02 main components: 1. Inlet Pickoff Sensor and 2. Outlet Pickoff Transmitter.

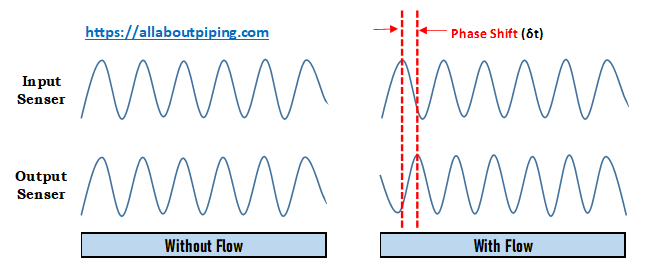

From the above animation, When there is no flow in the Coriolis mass flow meter both tube oscillates parallelly to each other and generate the same phase sine curve. While there is flow in the flow tubes a Coriolis force act on Flow measuring tubes.

During the flow of fluid natural frequency without a flow of fluid have the same sine-curve without any phase shift. But because of Coriolis forces a change in phase from Inlet pickoff sensor to Outlet Pickoff sensor.

During the flow, the Vibrating tube and mass of fluid couple together because of Coriolis force and causes twist in the flow tubes from Inlet to the outlet. This tube generates a phase shift between the signal generated and Signal Received.

This phase shift is directly proportional to mass flow rate and the Vibration frequency of the flow tube is also directly proportional to the density of the fluid. This phase shift becomes the key towards Coriolis mass flow meter working and measurement. As the Difference between phase shift increase Mass flow also increases.

More Resources: What Is RF Pad? How To Calculate Reinforcement pad dimensions?

What can be measured with a Coriolis flowmeter?

Coriolis Flowmeter principle makes it enable to measure multiple variables from a single mass flow meter with much accuracy. A Coriolis flow measurement device can measure the following:

- The density of the fluid

- The temperature of fluid flowing in Coriolis mass flow controller.

- The viscosity of the fluid.

The method of measurement of each variable is as follows:

Density measurement by Coriolis Flowmeter

A Coriolis flow meter phase shift provides the measurement of mass flow. As the density of fluid changes its Coriolis force also changes results in a change in phase. When a higher dense fluid is flowing in the tube Coriolis force will be less and less phase shift will there and Vice-versa.

This Coriolis density meter works on this principle. So when you change the density of fluid resonance frequency of fluid also changes and gives the basis of density measurement. During Coriolis flowmeter installation accuracy is checked for accurate measurement of fluid flow.

A Coriolis flow meter will provide the measurement of change in density of fluid flow not the exact density of the fluid. A Coriolis flow meter accuracy can be in the range of tolerance of ±0.0005 g/m³

Temperature measurement by Coriolis Flowmeter

As we know the density of fluid depends on temperature. As temperature will change fluid density too. So a Coriolis flowmeter can measure a change in temperature of fluid too.

Viscosity measurement by Coriolis Flow meter

The Middle section of the flow tube is equipped with a counter-oscillation mass. The motion produced because of this mass generates a shear force on the fluid flowing in the tube. As fluid viscosity changes, it changes the frequency of oscillation. Coriolis flowmeter and controller read this phase shift, calculate it, and convert it into a number that we can read.

Advantages of Coriolis flowmeter

Using Coriolis mass flow meter gives us some advantages as follows:

- Easy to implement and install in case of any fluid flow measurement.

- Doesn’t require any special build inlet and outlet connection.

- Can measure mass flow, Volume flow, Temperature, and Density with a single device.

- Highly accurate and reliable with low maintenance.

- Don’t have any effect on the accuracy of measurement with pressure, temperature, and viscosity.

- It can operate in bi-directional flow.

- Self-draining

Disadvantage of Coriolis flowmeter

As with other devices the are some disadvantageous too:

- Measurement effect by any gas inclusion in fluid flow.

- this device is vibration sensitive and can provide false output.

- Comparatively more costly than other mass flow meters.

- Has limited working temperature range.

- can not be used to measure fluid flow with low density and pressure.

- Restricted nominal size range. Can not be used for more than 8NB line size.

- Huge pressure loss when measuring a liquid with high saturated vapor pressure.

Application of Coriolis Flowmeter

A Coriolis mass flow meter is primarily used in scientific applications where it can measure both corrosive and clean fluid. This is also used in:

- Pulp and paper industries.

- Petroleum and Oil production.

- Chemical Industries.

- Waster water handling process.

- Used in Gas separator units.

Coriolis Flow meter installation Guide

Some points that should not be avoided during installation and fulfill Coriolis flow meter installation requirements:

- There should not be any vibration in the Piping system. This can interrupt and crate deviation in the accuracy of measurement.

- Both Sides of the flowmeter must be supported rigidly.

- Any mounting or clamping arrangement should be done carefully as per the recommendation of the manufacturer.

- If there is any chance of bubble formation in fluid, An air release device must be installed in its upstream flow.

- A control valve must be installed on the downstream flow of the Coriolis flow meter to increase backpressure and lower the chances of cavitation.

Coriolis Flow meter symbol

In a P&ID drawing is:

Conclusion

A Coriolis flow meter is a special kind of Mass flow meter that works on Coriolis force. This is also called an Inertial flow meter as oscillation and phase shift occur because of the inertial motion of fluid in the tube. Some of the bullet points of the Coriolis flow meter is:

- Coriolis flow meter names after french mathematician Gaspard-Gustave de Coriolis who invented the Coriolis effect.

- A Coriolis flow meter has 02 tubes for flow measurement.

- It can measure the mass flow, density, volume, temperature, and viscosity of a fluid according to its phase shift measured by pickoff sensors.

- This device doesn’t suitable for the measurement of Low viscous and low-pressure fluid.

- External vibration to the device affects measurement accuracy.

- Piping systems should be rigidly supported for accurate measurement.

- Coriolis mass flow meter is generally available up to 8″ NB only.